You use a crossing fitting when you want to connect four pipes at right angles. A four-way pipe fitting helps you manage flow in all directions. Cross fittings let you create strong, equal-sized connections for pipe fittings in high-pressure systems. You often see a cross fitting in lawn sprinkler setups or complex piping networks.

A 4 way cross fitting joins four pipes at right angles. It lets you control flow in many directions. It helps make strong pipe systems that do not leak.

Pick cross fittings by looking at material, connection type, and what your system needs. Galvanized malleable iron and stainless steel are strong. They do not rust easily and work well for hard jobs.

Install fittings the right way and check them often to stop leaks and damage. Always use the right pipe size, thread type, and pressure rating. This keeps your system safe and working well.

When you work with pipes, you often need to connect them in different directions. A crossing fitting helps you do just that. You use cross fittings when you want to join four pipes at right angles. Each pipe connects to one of the four outlets, making it easy to split or combine flows. This type of fitting is also called a cross.

You see cross fittings in many places, like plumbing, HVAC, and industrial systems. They let you build strong, stable pipe networks that can handle high pressure and heavy use. If you need to branch out or bring together several pipe runs, a crossing fitting is the tool for the job.

A cross fitting has a simple but powerful design. Picture a plus sign (+). Each arm of the cross has an opening for a pipe. All four outlets sit at 90-degree angles. This shape lets you connect pipes so they cross or branch out in different directions. The cross fitting makes it easy to control how water, gas, or steam moves through your system. You can send flow from one pipe into three others, or combine flows from several pipes into one. Cross fittings have thick walls and are made from strong materials like malleable iron.

This helps them handle high pressure and keeps your system safe. The threaded ends on each outlet make installation quick and secure. You get a tight seal that prevents leaks. Cross fittings are key parts of complex pipe systems, giving you the flexibility and strength you need.

There are many kinds of cross fittings. Each kind works best for certain jobs. You should choose the right cross for your pipes. Let’s look at cross fittings by material, connection, and design.

Cross fittings are made from different materials. Each material is good for different uses. Some work better for water. Some are better for chemicals. Some are strong for heavy-duty jobs. Here are the most common materials for cross fittings:

| Material | Advantages | Disadvantages / Notes |

|---|---|---|

| PVC | Light, does not rust | Not good for hot water |

| Copper | Strong, works for hot and cold water | Costs more |

| Stainless Steel | Very strong, does not rust, handles high pressure | Expensive |

| Brass | Does not rust, lasts long | Heavier than PVC |

| Aluminum | Light, resists chemicals | Not as strong as steel |

| Titanium | Does not rust, can be recycled | Costs a lot, used for special jobs |

| Cast Carbon Steel | Very strong, flexible design | Costs more than iron fittings |

| Malleable Iron | Very strong, tough, does not rust | Needs skilled workers to install |

PVC 4 way pipe connectors are used in homes. They are light and easy to put in. Stainless steel 4 way pipe connectors are good for hot water or high pressure. Metal 4 way pipe connectors like malleable iron or brass are strong for hard jobs. ABS 4 way pipe connectors are also used for light jobs.

| Material | Size Range (inches) | Pressure Rating / Class | Connection Type |

|---|---|---|---|

| Malleable Iron | 0.062 to 4.000 | 150# | Threaded, Compression fittings |

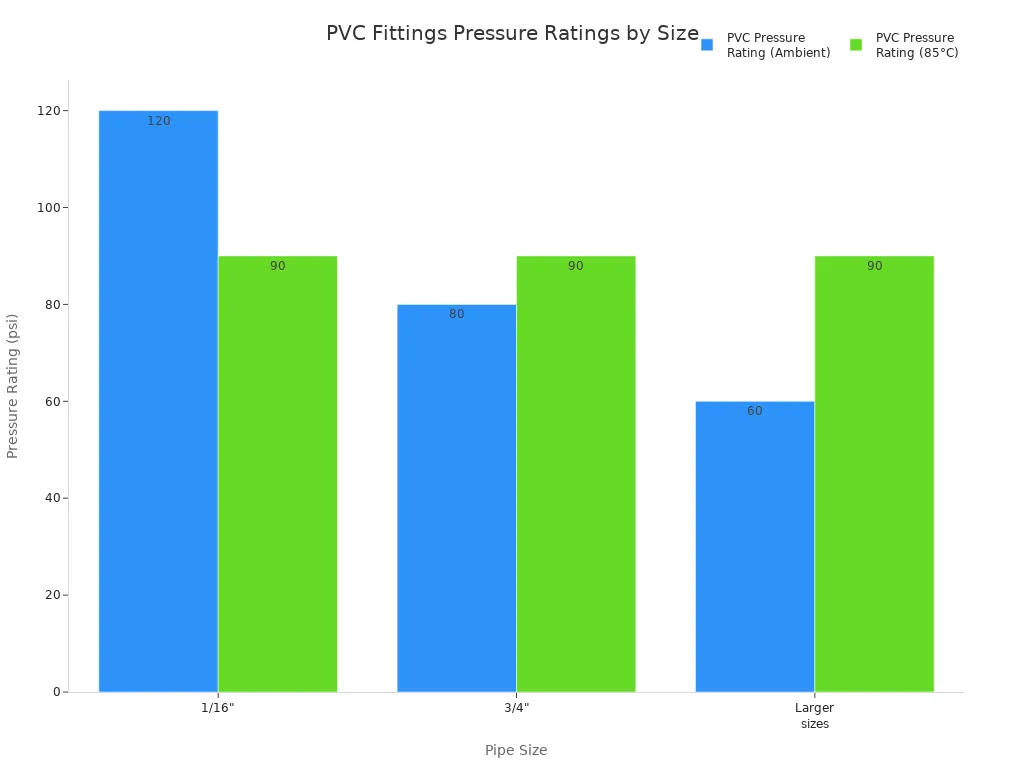

| PVC | 1/16 to 3/4+ | 120 psi (normal), 90 psi (up to 85°C) | Female connections |

| Stainless Steel | 0.125 to 1.000+ | ANSI B16.11; 3M, 6M, 9M classes | Threaded, Socket weld |

For outdoor or high pressure jobs, galvanized malleable iron is a great choice. It is strong, does not rust, and lasts a long time. The zinc layer stops rust, so cross fittings last longer in wet places.

→ Tip: Always check the material before you buy cross fittings. The right material keeps your pipes safe and working well.

Cross fittings have different ways to connect. You should match the connection to your needs. Here is how the main connection types compare:

| Connection Type | Installation Complexity | Application Suitability | Advantages | Disadvantages |

|---|---|---|---|---|

| Threaded | Easy to put in, can be taken apart | Good for low or medium pressure | Cheap, works well | Not for high pressure, may rust |

| Welded | Needs skilled workers, risk of mistakes | Best for high pressure, strong joints | Very strong, no leaks | Needs skill, can bend out of shape |

| Flanged | Slower, uses bolts and gaskets | Works for many pipes, high pressure | Very strong, easy to take apart | Costs more, takes longer to put in |

Threaded cross fittings are common in plumbing and HVAC. You can put them in fast and take them apart to fix things. Welded cross fittings are best for big jobs where you need strong, leak-free joints. Flanged cross fittings are good for large systems that need high pressure and easy fixing.

The 4 way pipe connector from JIANZHI uses threaded connections. This makes it easy to install and gives a tight seal. You can trust these cross fittings for high pressure jobs.

There are many types of 4 way pipe connectors. Some are for plumbing, some for big jobs, and some for furniture or racks. The most common types of 4 way pipe connectors are:

Galvanized malleable iron cross fittings

Stainless steel cross fittings

Brass cross fittings

Black iron cross fittings

PVC 4 way pipe connectors

ABS 4 way pipe connectors

Metal 4 way pipe connectors like galvanized malleable iron and stainless steel are strong and last long. These cross fittings handle high pressure and do not rust. You see them in water, heating, and chemical systems. PVC and ABS 4 way pipe connectors are good for lighter jobs like home plumbing or shelves.

Here are the good things about galvanized malleable iron cross fittings:

Very strong: Handles heavy loads and high pressure.

Does not rust: Zinc layer keeps rust away, even in wet places.

Tough: Hard to crack or break.

Lasts long: Saves money over time.

Works with many pipes: Can use with steel, copper, brass, and more.

Easy to put in: Can bend or shape on-site for tricky spots.

Here is a quick comparison:

| Feature | Galvanized Malleable Iron Fittings | Black Iron Fittings |

|---|---|---|

| Corrosion Resistance | High, good for outside and wet places | Low, best for dry indoor use |

| Lifespan | Longer, because of zinc protection | Shorter in wet places |

| Ideal Applications | Water supply, outside, drinking water systems | Gas lines, indoor fire systems |

| Strength & Durability | Strong, tough | Strong, not as rust-proof |

| Cost | Costs a bit more | Costs less |

| Installation | Needs skilled threading | Can be welded, easier for some jobs |

If you want a cross fitting that meets world standards, the JIANZHI 4 Way Pipe Fitting Equal Cross is a smart choice. It is made from top malleable iron, hot-dip galvanized with thick zinc. It meets EN10242, ANSI B16.3, and ISO 49 standards. It handles up to 25 BAR (363 PSI) and up to 200°C (392°F). You can use it for water, gas, steam, or chemicals. The careful casting and tight controls mean you get perfect fit and easy installation every time.

You see these cross fittings in plumbing, big pipelines, heating systems, and more. They are strong, useful, and built to last. If you need help picking the right cross fittings or want to learn more about 4 way pipe connectors, contact JIANZHI. We can help you find the best pipe fittings for your project.

Cross fittings are used in homes and big buildings. They connect four pipes at right angles. This makes it easy to split or join water flow. Here are some ways people use cross fittings in plumbing:

Four drainage pipes can join a main soil stack.

Supply lines can merge into a main water line or sprinkler system.

Vent pipes can join a main vent stack.

Gas lines can combine into one supply line.

A 4 way pipe connector works for drainage, irrigation, venting, and gas lines. These fittings work with steel, cast iron, brass, and PVC pipes. They make strong connections that do not leak and last a long time.

Factories and chemical plants use cross fittings a lot. A 4 way pipe connector helps build complex pipe networks. These networks move water, gas, or chemicals. Cross fittings handle high pressure and tough jobs. Stainless steel and malleable iron cross fittings do not rust. They stand up to heat and chemicals. You see these fittings in water treatment plants, oil pipelines, and chemical lines. They help control flow and keep pressure steady. They make sure your system is safe and works well.

Cross fittings are important in HVAC and fire protection systems. A 4 way pipe connector helps route refrigerants and chilled water in HVAC setups. These fittings let you build networks to keep air cool or warm. In fire protection, cross fittings send water to different branches. This makes sure every area gets water. The right fittings keep your system safe and stop leaks. They handle high pressure in emergencies. JIANZHI cross fittings are extra strong and do not rust. You can trust them in harsh places.

→ Tip: Cross fittings have many benefits. They lower leak risks, make installation easier, and work well even in tough places. If you need help picking fittings, contact JIANZHI.

You can connect four pipes at right angles. This makes your system more flexible and helps you control flow in different directions.

Yes, you can. Just make sure you pick the right material and check the pressure rating for your system.

You can always reach out to our team for advice. Contact us if you need help with product selection or technical support.

Products Category

Products

News

Related Information

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania