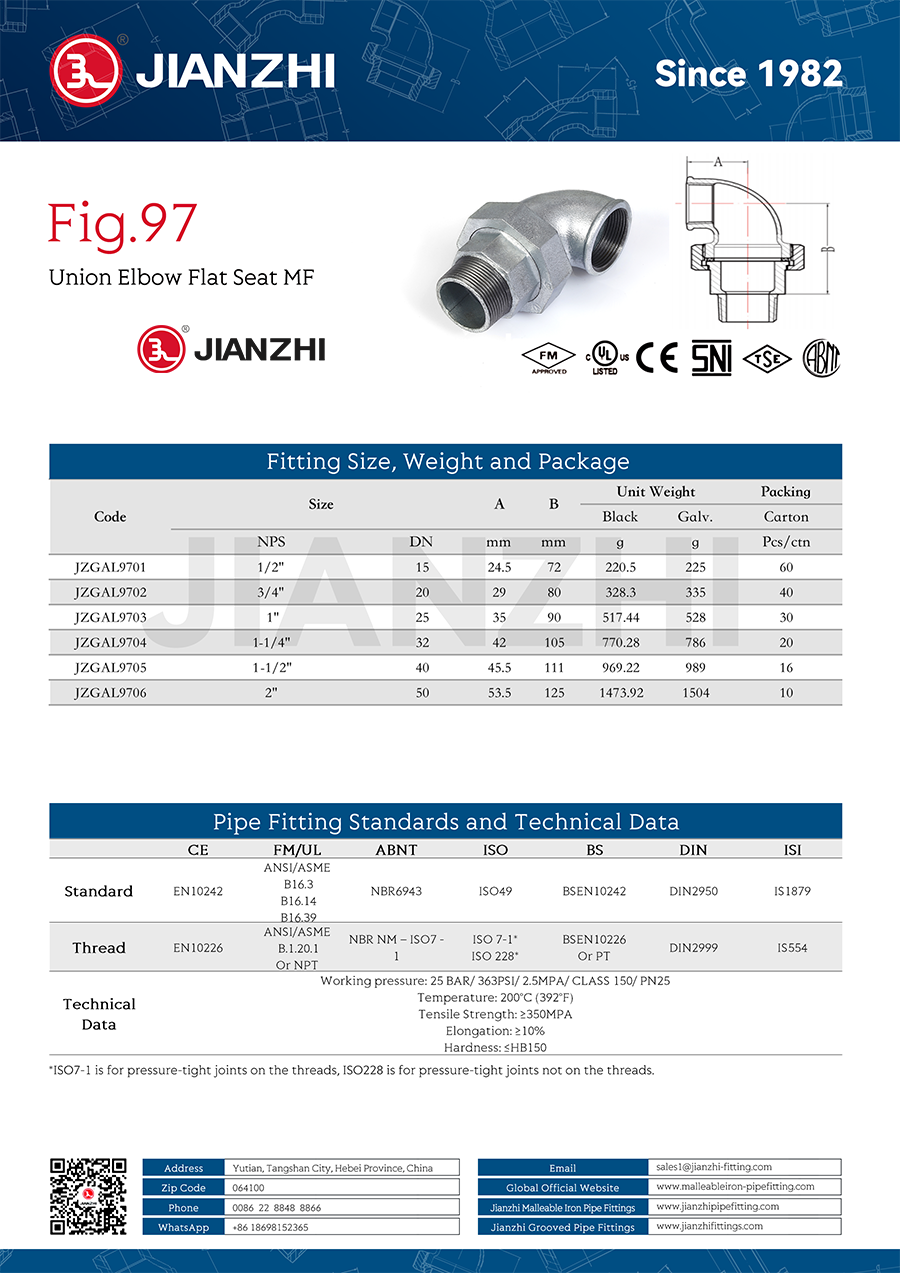

Size: 1/2''-2''(DN15-DN50)

Standard: EN10242 / ANSI / ASME B16.3 / DIN2950 / IS0 49 / NBR6943 / IS1879 / BS EN10242

Threaded Standard: EN10226 / ASME B.1.20.1 / DIN2999 / ISO7-1 / ISO228 / IS554 / BS EN10226

Work Pressures: PN25 / 2.5Mpa / 363PSI /CLASS 150 / 25Bar

UL Listed /FM Approved /CE /ABNT /TSE /SNI /ISI

Product Description

Maximum Pressure: 25 BAR (363PSI) (2.5MPA) CLASS 150

Maximum Temperature: 200°C (392°F)

Tensile Strength: 350MPA

Hardness: HB150 (Brinell)

Elongation Rate: 10%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Malleable Iron

Galvanized pipe fittings refer to the treatment of galvanized pipe fittings. The base of the pipe and molten bath have complex physical and chemical reactions, forming a zinc ferroalloy layer with a close corrosion-resistant structure.

The alloy layer is integrated with a pure zinc layer and pipe base. Therefore, it has strong corrosion resistance. The main purpose of galvanizing is to enhance the corrosion resistance of pipe fittings. Hot-dip galvanized pipe fittings are mainly used for conveying gas, heating, and other pipeline projects. If the steel pipe body needs to be galvanized anti-corrosion treatment, the corresponding connecting pipe fittings should also be galvanized.

Galvanized male seat elbows are widely used in various piping systems where durability, sealing performance, and corrosion resistance are essential. Common applications include:

● Industrial fluid systems – for oil, gas, and chemical pipelines.

● HVAC systems – reliable elbow joints for heating and cooling pipes.

● Water supply lines – efficient flow redirection in plumbing networks.

● Fire protection systems – secure, corrosion-resistant connections.

● Compressed air systems – airtight, threaded joints for industrial use.

● Agricultural irrigation – rust-resistant elbows for outdoor pipelines.

Their union and conical seat design allows for easy installation, tight sealing, and long service life across demanding environments.

Degreasing → Rinsing → Pickling → Cleaning → Fluxing→ Hot air drying → Hot-dipped galvanizing → Cooling →Passivation and Rinsing.

▶ Hot dipped galvanized pipe fittings:thick zinc layer, uniform zinc layer on the inner and outer walls, long service life.

▶ Electro galvanized pipe fittings:thin zinc layer, smooth and beautiful surface, lower cost, but inner surface zinc layer is too thin.

Product Dimensions

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania