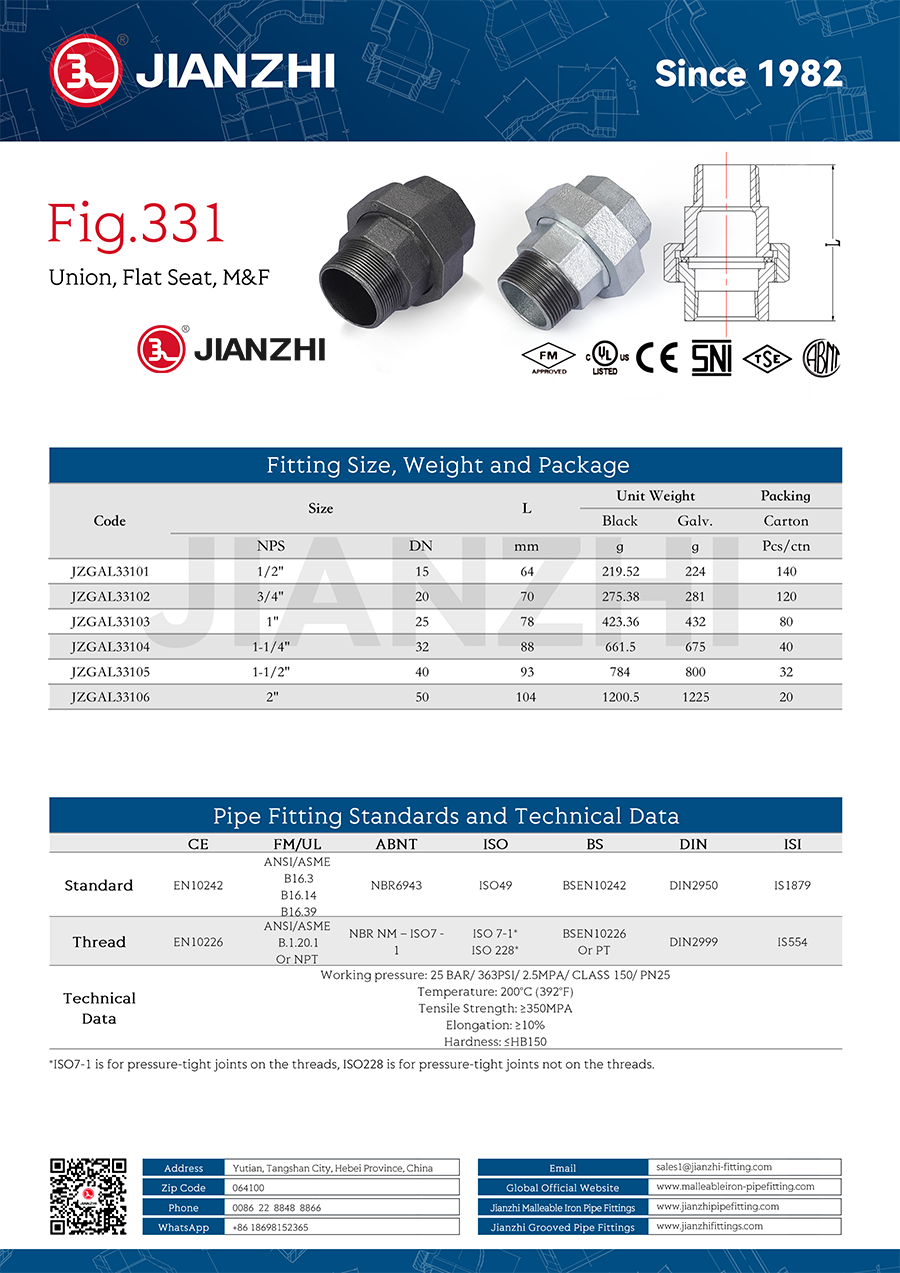

Size: 1/8''-6''(DN6-DN150)

Standard: EN10242 / ANSI / ASME B16.3 / DIN2950 / IS0 49 / NBR6943 / IS1879 / BS EN10242

Threaded Standard: EN10226 / ASME B.1.20.1 / DIN2999 / ISO7-1 / ISO228 / IS554 / BS EN10226

Work Pressures: PN25 / 2.5Mpa / 363PSI /CLASS 150 / 26Bar

UL Listed /FM Approved /CE /ABNT /TSE /SNI /ISI

Product Description

Maximum Pressure: 25 BAR (363PSI) (2.5MPA) CLASS 150

Maximum Temperature: 200°C (392°F)

Tensile Strength: 350MPA

Hardness: HB150 (Brinell)

Elongation Rate: 11%

Suitable Applications: Water, Oil, Gas, Petro-Chemical

Material: Malleable Iron

Galvanizing after processing:

According to the demand, hot-dip plating and electroplating are used for the construction and support pipe fittings. Generally, galvanized pipe fittings are processed first and then galvanized, which has a low cost. The disadvantages are that the inner surface is not easy to be plated, the black and red rust spots are serious, and the coating thickness is not easy to control. In the plating process, the threads are seriously damaged due to collision, which directly affects the accuracy of the threads and makes them difficult to install.

In order to avoid the above defects, the cost of the pipe fittings is increased, and all the pipe fittings are galvanized before processing to ensure thread accuracy.

Product Dimensions

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania