Sep. 29, 2022

Mechanical pipe connectors provide a flexible and reliable way to connect pipes of all sizes without flaming or welding. Let us get a Mechanical Piping Connectors Explored of mechanical tee and cross from this JIANZHI blog.

Mechanical pipe connectors are a special type of grooved pipe fittings, which are mainly divided into mechanical tee and mechanical cross. According to the connection method of the branch pipe, it can be divided into groove connection and threaded connection. There are four types in total. The following four pictures respectively show the grooved mechanical tee, threaded mechanical tee, grooved mechanical cross, and threaded mechanical cross of Jianzhi Group.

In the construction process, a mechanical tee is used when opening a hole on the main pipe to lead out a branch pipe with a different diameter. There are two forms of groove connection and threaded connection.

There are usually several reasons for this type of connection:

l A branch pipe needs to be led out somewhere on the installed main pipe.

l When one or more reducing branch pipes need to be drawn out from a certain part of a pipe with a fixed length (usually 6 meters) (if a reducing tee is used to lead the branch pipe, the main pipe must be cut off, which brings inconvenience).

l To save costs. (The material cost of using a reducing tee is higher than that of using a mechanical tee)

Under normal circumstances, when the outer diameter of the main pipe is ≥33, a mechanical tee is used, and a U-shaped mechanical tee is usually used when the diameter is between 33 and 60. The outer diameter of the branch pipe of the U-shaped mechanical tee is generally between 21 and 33 (that is, Between 1/2" inch and 1" inch), the connection method is threaded connection; mechanical tee is mostly used between 60 and 219 calibers, and there are two connection methods: groove connection and screw connection. The demand is not much different.

It is used when it is necessary to open two holes in the symmetrical direction of the main pipe to lead out two branch pipes with different diameters. There are two forms of groove connection and threaded connection, and the reason for this connection is the same as that of the mechanical tee.

Because there is no need for a grooving process and the use of clamp connections, the cost of using a mechanical tee or mechanical cross is lower than using a grooved tee or a grooved cross. If it can be applied to both types of connection methods, the mechanical pipe connector is a better choice for economic reasons.

When the mechanical tee is connected, the clearance between the mechanical tee and the hole should be checked, all parts should be even and then tightened in place. The spacing between the mechanical tee openings should not be less than 1m, and the spacing between the mechanical cross openings should not be less than 2m.

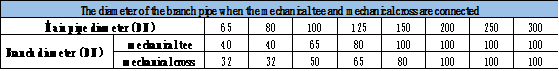

When the mechanical tee and mechanical cross are connected, the diameter of the branch pipe shall meet the requirements in Table 1. When the connection between the main pipe and the branch pipe does not conform to Table 1, grooved tee and cross pipe fittings shall be used for the connection.

Table 1

The groove connection should be made of a black EPDM rubber C-type sealing ring. The elasticity should be good, and there should be no damage or deformation. There should be a gap in the middle of the C-type sealing ring after installation and compression.

Mechanical tee using black EPDM

Adjustable: mechanical pipe connectors offer easy implementation, reliable performance and options to fit almost any conceivable pipe size.

Easy to remove: mechanical pipe connectors excel in systems that require frequent disassembly or maintenance and in situations where pipe configurations may be changed periodically.

Easy to handle: Once the pipe or fitting is slotted, connecting the assembly is as simple as aligning the coupler and tightening the fasteners. No grooves are required and you can safely connect two pipes without the need to locate flanges, grooves and weld or thread positions

Wide range of applications: for hot oil/water mixtures of different concentrations, hydrocarbons, air with oil vapour, vegetable and mineral oils, as well as automotive fluids (e.g. engine oils and transmission fluids) and unprocessed and potable water

l Check the drilling machine to ensure safe use.

l Preparation of materials and tools, including pipes, steel tapes, wrenches, vernier calipers, spirit levels, lubricants, etc.

l Play the ink line on the steel pipe to determine the opening position of the joint branch pipe

l Fix the chain hole punching machine at the predetermined hole position of the steel pipe.

l Start the motor, turn the hand wheel, slowly approach the drill bit to the steel pipe, and add lubricant to the drill bit to protect the drill bit, and complete the drilling on the steel pipe.

l Stop the machine, shake the handwheel, turn on the chain, remove the hole punch, clean up the drilled metal blocks and the residue at the hole, and use a grinder to smooth the hole.

l Put the clamp on the steel pipe, pay attention that the mechanical tee should be concentric with the hole, the gap between the rubber sealing ring and the hole is even, and the tightening bolts should be in place.

l If it is a mechanical cross, be sure to ensure that the holes on both sides of the steel pipe are concentric when opening the hole, otherwise, when the installation is completed, the rubber ring may be broken and the water passage area may be affected.

According to the principle of installing large-diameter, main pipe, and riser first, and then installing small-diameter and separate pipes, during the installation process, they must be installed in sequence, without skipping or segmented installation, so as to avoid difficulty and influence on the connection between segments. Overall performance of the pipeline.

l Apply lubricant to the mechanical tee or cross.

l Put the sealing ring into the sealing groove of the mechanical tee or cross.

l Insert the mechanical tee or cross into the steel pipe hole.

l Tighten the bolts with a force limit wrench.

After the pipeline is installed, the system pressure test should be carried out. Before the system pressure test, check whether the relevant components are in place. The installed pipeline may sag. If the sag radian is large, a bracket can be added; if the radian is small, the radian will disappear naturally when the pressure in the pipeline increases. Only when the system pressure test verifies that there is no leakage in the piping system can it be proved that the sealing of the piping system is good. Otherwise, the leakage location should be carefully checked and the relevant parts should be replaced in time.

I believe that you have a certain understanding of mechanical pipe connectors. If you want to know more knowledge, please click the link below to enter our website. We are now working on building our website into a huge knowledge treasure house about the pipe fittings industry, which will store a large number of industry knowledge articles, you are welcome to explore. https://www.malleableiron-pipefitting.com/

Jianzhi is a leader manufacturer in pipe fittings in China. Our wide selection and decades of experience allow us to assist companies large and small in a variety of industries. Contact us today to discuss your requirements and our expert sales analysts can help you find the ideal mechanical pipe connector for your project!

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania