Nov. 22, 2022

GI pipe fittings are a type of hardware product that we often come into contact with in our lives. As one of the products of malleable pipe fittings, what is the difference between GI pipe fittings and other malleable pipe fittings? What is the treatment process for GI fittings? What are the advantages of GI fittings? And how to save GI fittings? This article will answer you one by one.

Table of contents

● GI pipe fittings and BMI pipe fittings

● Hot-dip galvanizing and Cold galvanized

● Benefits of using GI pipe fittings

● Save the GI fittings

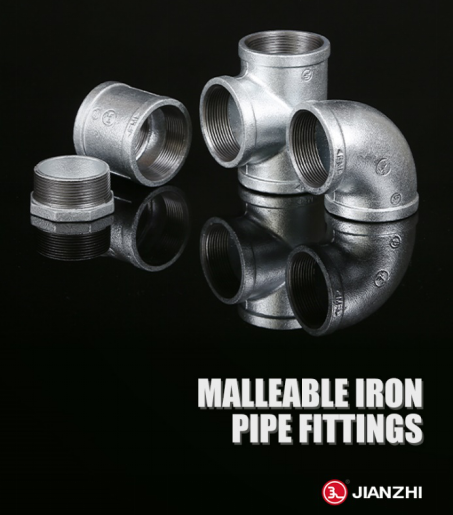

GI pipe fittings are a type of malleable pipe fittings. According to the different surface treatment methods, malleable pipe fittings can generally be divided into two categories:

Non-galvanized black malleable pipe fittings, also known as BMI, are malleable pipe fittings that have not undergone special surface treatment. This kind of pipe fittings is generally used in fields that have low requirements for pipe fittings to prevent rust or customers who want to process the surface by themselves.

BMI pipe fittings of Jianzhi Group

There is also a galvanized pipe fitting, which is a GI pipe fitting. The surface of GI pipe fittings needs to be galvanized to enhance the rust and corrosion resistance of the pipe fittings.

GI pipe fittings of Jianzhi Group

GI pipe fittings can be divided into hot-dip galvanizing and cold-dip galvanizing in terms of galvanizing methods.

Hot-dip galvanizing (HDG) is a common method of galvanizing that involves completely immersing iron or steel in molten zinc. The formation process of the hot-dip galvanized layer is the process of forming an iron-zinc alloy between the iron substrate and the outermost pure zinc layer. During hot-dip galvanizing, a layer of iron-zinc alloy layer is formed on the surface of the workpiece to combine the iron and pure zinc layer. The advantages of hot-dip galvanizing are strong anti-corrosion ability, good adhesion, and hardness of the galvanized layer, so as to achieve the purpose of anti-corrosion.

Hot-dip galvanizing production line of Jianzhi Group

Cold galvanizing is also called electro-galvanizing. Electro galvanizing is an electrochemical method that uses zinc ingots as the anode and steel as the cathode. After the zinc atom loses electrons, it dissolves into the electrolyte in an ionic state, and the zinc ions get electrons on the steel, and the electrons are reduced to zinc atoms and deposited on the surface of the steel. The amount of zinc used in cold galvanizing is small, only 10-50g/m2. It is the process of attaching a metal film to the surface of metal or other materials by electrolysis. The process of forming a uniform dense metal layer prevents corrosion, improves wear resistance, conductivity, and reflectivity, and enhances aesthetics.

Jianzhi Group's cold galvanizing production line

◎ Low processing cost: the cost of anti-rust GI pipe fittings is lower than that of other paint coatings.

◎ Durable and durable: GI pipe fittings have the advantages of a glossy surface, uniform zinc layer, no missing plating, no dripping, and so on. Standard GI pipe fittings can be maintained for more than 50 years without repair; in urban or offshore areas, standard GI pipe fittings can be maintained for 20 years without repair.

◎ Good reliability: the galvanized layer is combined with the pipe fittings and becomes a part of the GI pipe fittings on the surface of the pipe fittings, so the durability of the coating is more reliable.

◎ The toughness of the coating is strong: the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

◎ Comprehensive protection: the surface of GI pipe fittings is all galvanized, even in depressions, sharp corners, and hidden places can be fully protected.

◎ Save time and effort: the galvanizing process is faster than other coating construction methods and can avoid the time required for painting on the construction site after installation.

In addition, I will introduce the storage method of GI pipe fittings:

The site or warehouse where GI pipe fittings are placed should be in a clean and well-drained place, away from factories and mines that produce harmful gases or dust. Weeds and all debris should be removed on the site, and the GI pipe fittings should be kept clean. Do not stack together with acid, alkali, salt, cement, and other corrosive materials in the warehouse. GI pipe fittings of different varieties should be stacked separately to prevent confusion and prevent contact corrosion.

GI fittings should be stored in the warehouse. The warehouse should be selected according to geographical conditions. Generally, an ordinary closed warehouse is used, that is, a warehouse with a roof, a wall, tight doors and windows, and a ventilation device.

Jianzhi Group's foreign trade warehouse

I believe you will have a comprehensive understanding of GI pipe fittings after reading this article. Of course, these contents cannot be said to be very comprehensive. If you want to know more, you can open the following link to our website. The official website of Jianzhi Group is a huge repository of knowledge about malleable pipe fitting products. I believe you can learn more here.

https://www.malleableiron-pipefitting.com/

Of course, you can also click the link below to enter our YouTube homepage, where there are more wonderful videos. You can have a more intuitive understanding of the GI pipe fittings produced by Jianzhi Group, and you are also welcome to inquire.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania