Jan. 15, 2026

In the highly regulated industrial landscape of 2026, the procurement of a malleable iron pipe fitting has evolved from a simple commodity purchase into a strategic exercise in risk mitigation. As global infrastructure demands shift toward higher safety margins, the ability of a pipe fitting to consistently perform under a working pressure of 2.5 MPa (363 PSI) is paramount.

This guide provides a comprehensive framework for sourcing managers and engineers, bridging the gap between metallurgical theory and supply chain logistics. By analyzing the interplay between international standards (ISO, EN, ASME), the physics of Hoop Stress, and the critical 96-hour annealing process, we demonstrate how Jianzhi’s "Heavy Type" engineering eliminates the hidden costs of system failure. From the specialized requirements of a fire fighting pipe fitting to the sacrificial protection of a gi pipe fitting, this document serves as the definitive blueprint for ensuring zero-defect delivery and 50-year service life in critical fluid and gas networks.

● The "Heavy Type" Safety Buffer: Always specify the "Heavy Type" design for Class 150 systems. Increased wall thickness is the most effective defense against internal pressure, as defined by the formula $Sh = (P \·d) / (2·t).

● Ductility as Insurance: Ensure a minimum of 10-12% elongation. This high level of ductility, achieved through a proprietary 96-hour annealing cycle, prevents brittle fractures during seismic events or rapid thermal shocks in a fire fighting pipe fitting system.

● Precision Threading Protocol: Demand CNC-machined threads with a strict 1:16 taper. Whether using NPT or BSPT, geometric accuracy is the only way to guarantee a metal-to-metal interference seal at 2.5 MPa.

● Corrosion Life-Cycle Planning: For exposed or water-based systems, prioritize the gi pipe fitting with hot-dip galvanization. Use the coating life formula L = h / R to verify that the zinc thickness ($h$) meets the project's long-term environmental durability requirements.

● Third-Party Validation: For high-stakes applications, only source malleable iron pipe fitting products that carry verified UL Listed and FM Approved marks, ensuring compliance with global insurance and safety codes.

● Zero-Defect Mandate: Eliminate on-site rework costs by requiring 100% air-under-water testing from the manufacturer, rather than standard batch sampling.

1. The Global Supply Landscape for Pipe Fitting Products

2. Understanding International Standards: The Blueprint for Quality

3. Material Excellence: From White Iron to Ferritic Malleability

4. Fire Fighting Pipe Fitting: Critical Safety Specifications

5. Galvanized (GI) Pipe Fitting vs. Black Fittings: The Finish Guide

6. Precision Threading: The Key to Leak-Free Supply

7. Structural Integrity: Why "Heavy Type" Dominates Sourcing

8. Supply Chain Logistics: Packaging, Quality, and Lead Times

9. Frequently Asked Questions (FAQ) for Sourcing Managers

10. Conclusion & Technical Bibliography

The current supply landscape is defined by a massive surge in demand for reliable, high-pressure components capable of sustaining 2.5 MPa (363 PSI). However, this demand is met with a fragmented manufacturing base, where the disparity between "price-driven" casting and "performance-driven" engineering has never been wider. For procurement managers, navigating this landscape requires a shift from simple unit-cost analysis to a strategic evaluation of manufacturer capability and material integrity.

In decades past, a malleable iron pipe fitting was often sourced solely on price per kilogram. Today, the "Total Cost of Ownership" (TCO) model dominates. Industrial end-users have realized that the cost of a single leak—in terms of water damage, gas escape, or system downtime—dramatically exceeds the marginal savings of a cheaper component.

Consequently, the 2026 supply market is seeing a flight to quality. Sourcing agents are increasingly bypassesing generic trading houses to partner directly with manufacturers like Jianzhi who control the entire metallurgical process. This shift is particularly evident in the procurement of fire fighting pipe fitting systems, where the insurance and life-safety implications demand a level of "Material Honesty" that commodity foundries cannot provide.

A significant challenge in the current global supply chain is the prevalence of "Material Optimization." Many budget-oriented factories have reduced the wall thickness of their products to the absolute minimum required by standard tolerances to save on raw iron and energy. While these "Light Type" fittings may pass a static pressure test in a laboratory, they lack the "Structural Buffer" needed to survive real-world stresses such as water hammer, seismic shifts, or the high torque applied during installation.

Jianzhi has defined its market position through the "Heavy Type" philosophy. By ensuring that every galvanized pipe fitting and black fitting contains significantly more mass than the industry average, we eliminate the structural risks associated with thin-walled castings. This extra mass is a physical manifestation of supply chain safety, providing the "Hoop Stress" resistance necessary for a permanent, 2.5 MPa-rated installation.

In an era of volatile logistics and rising energy costs, "Supply Chain Certainty" is the ultimate goal for the international distributor. This certainty is built on two pillars: consistency and verification.

Consistency: Through high-pressure vertical molding and CNC machining, Jianzhi ensures that a gi pipe fitting produced in our facility is identical across every batch.

Verification: Procurement protocols now demand 100% verification. By moving away from batch sampling to a 100% air-under-water testing mandate, Jianzhi provides a "Zero-Defect" guarantee that simplifies the procurement process for global partners.

By understanding these landscape dynamics, sourcing managers can move beyond the "commodity trap" and select a malleable iron pipe fitting partner that adds long-term value to their infrastructure portfolio.

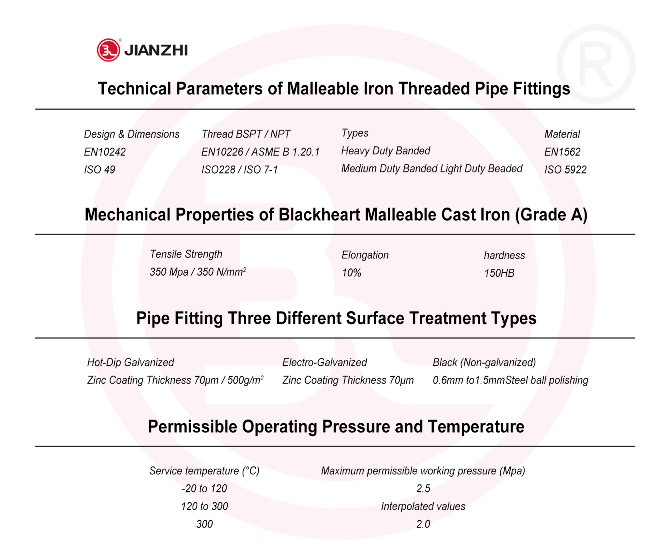

For a gi pipe fitting or a black iron component to be rated for 2.5 MPa (363 PSI) service, it must pass a series of rigorous geometric and metallurgical tests defined by global bodies. At Jianzhi, our production lines are synchronized with these standards to ensure that every export batch meets the specific regulatory requirements of the destination country.

The most widely recognized standards for the malleable iron pipe fitting are ISO 49 and its European counterpart, EN 10242. These documents classify fittings based on their design and the rigor of their manufacturing process.

A key distinction for procurement managers is the "Design Symbol A" classification. To achieve this rating, a manufacturer must prove that their fittings are made from high-grade malleable iron (ferritic) and that they meet the strictest dimensional tolerances. Jianzhi fittings are proudly marked with this symbol, signifying that our galvanized pipe fitting products possess the highest level of material purity and structural thickness. This classification is particularly critical for a fire fighting pipe fitting system, where the failure of a single joint can compromise an entire life-safety network.

For projects utilizing American engineering protocols, the ASME B16.3 standard is the governing authority. This standard defines the pressure-temperature ratings for Class 150 and Class 300 fittings. While many "Light Type" competitors struggle to maintain integrity at the upper limits of these ratings, Jianzhi’s "Heavy Type" philosophy ensures that our malleable iron pipe fitting products exceed the burst-pressure requirements mandated by ASME. This compliance is essential for the North American Oil & Gas and HVAC sectors, where safety margins are strictly enforced by local building codes.

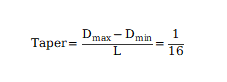

The most critical geometric standard for any threaded pipe fitting is the taper ratio. Both the British (BSPT) and American (NPT) standards require a precise 1:16 taper. This means for every 16 units of length, the diameter changes by 1 unit.

Taper Ratio = (D1 - D2) / L = 1 / 16

Where:

D1 = Major diameter at the pipe end.

D2 = Minor diameter at the start of the thread.

L = Length of the thread.

If a gi pipe fitting deviates from this 1:16 ratio, it will either "bottom out" too early or fail to create a metal-to-metal seal, leading to leaks even if high-quality sealant is used. Jianzhi utilizes CNC machining to ensure this taper is absolute, providing the "Geometric Reliability" needed for modular construction and prefabricated pipe spools.

By strictly following these blueprints, Jianzhi ensures that its malleable iron pipe fitting supply is ready for the global stage. Whether it is a fire fighting pipe fitting requiring UL/FM certification or a standard gi pipe fitting for a water grid, our adherence to ISO, EN, and ASME standards is your guarantee of field-ready performance.

The transition from a raw casting to a high-performance malleable iron pipe fitting is a journey of metallurgical transformation. At the foundry level, the "Material Excellence" of a pipe fitting is not defined by its shape, but by its internal crystalline structure. To produce a fitting that can withstand the rigors of a 2.5 MPa system, one must master the delicate process of heat treatment that turns brittle "white iron" into the resilient, ductile material known as ferritic malleable iron.

At Jianzhi, we believe that the soul of the malleable iron pipe fitting lies in its annealing cycle. Many suppliers in the global market prioritize speed and energy savings, but our "Material Excellence" philosophy dictates that quality cannot be rushed.

When iron is first cast, it exists as "white iron," where the carbon is chemically combined with iron in the form of iron carbide (Fe3C). In this state, the pipe fitting is extremely hard but as brittle as glass; it would shatter under the torque of a pipe wrench. To make it "malleable," the carbon must be forced to change its form.While many competitors utilize a shortened 48 or 72-hour annealing process to reduce costs, Jianzhi adheres to a strict 96-hour annealing cycle. This extended duration in our computer-controlled furnaces ensures that the iron carbides fully decompose into "temper carbon" (graphite) nodules. These nodules are suspended within a soft, ferritic metal matrix. This specific microstructure is what allows a gi pipe fitting to bend and deform without fracturing, a property that is essential for surviving the mechanical stresses of high-pressure installations.

In the world of structural engineering, the "Safety Buffer" of a material is measured by its elongation. This is the percentage that a metal can stretch or "give" before it finally fails. For a malleable iron pipe fitting, higher elongation directly translates to higher safety.

Standard industry requirements often settle for a 5% or 6% elongation. However, Jianzhi’s refined metallurgy consistently achieves an elongation of 10-12%.

●Seismic Resilience: In earthquake-prone regions, a fire fighting pipe fitting must be able to absorb the energy of building shifts. Brittle fittings will snap, but Jianzhi’s ductile fittings flex, maintaining the integrity of the water supply during a disaster.

●Installation Torque: When a technician applies high torque to seal a galvanized pipe fitting, the wedge effect of the tapered thread places immense internal tension on the fitting's hub. Our 12% elongation ensures the hub can expand slightly rather than cracking under pressure.

Material excellence also depends on what is not in the iron. Jianzhi utilizes electric induction melting rather than traditional cupola furnaces. This allows us to precisely control the chemical "recipe" of our iron. By minimizing impurities like sulfur and phosphorus, we prevent the formation of "hot tears" and internal porosities. This chemical purity ensures that every malleable iron pipe fitting has a uniform density, which is critical for the 100% air-tightness required in gas and vacuum lines.

For a sourcing manager, "Material Excellence" is the best defense against project delays. A pipe fitting made from high-quality ferritic malleable iron is easier to thread, easier to install, and far less likely to fail during the commissioning phase of a project. Whether you are specifying gi pipe fitting for a commercial water grid or black fittings for an industrial steam line, the metallurgical superiority of the Jianzhi brand ensures that the material properties match the engineering demands of the 21st century.

Property | Standard Requirement | Jianzhi "Heavy Type" |

Annealing Time | 48 - 72 Hours | 96 Hours |

Microstructure | Mixed Pearlite/Ferrite | Pure Ferritic Matrix |

Elongation (%) | 5% - 8% | 10% - 12% |

Tensile Strength | 300 MPa | 330+ MPa |

Application | Light Commercial | Industrial / 2.5 MPa |

In the architecture of active fire protection, the fire fighting pipe fitting is the silent guardian of the building. When a fire occurs, these components are suddenly subjected to extreme hydraulic pressure, thermal shock, and mechanical vibration. Unlike standard plumbing, a failure in a fire suppression network is not merely a maintenance issue—it is a life-safety catastrophe. Therefore, the sourcing of malleable iron pipe fitting products for fire safety requires a level of scrutiny that goes far beyond typical industrial requirements.

For a pipe fitting to be integrated into a certified fire sprinkler or standpipe system, it must meet the rigorous survival criteria of global insurance and safety bodies. At Jianzhi, we engineer our fire-specific fittings to ensure that when the heat rises, the system remains unyielding.

The primary filter for any procurement manager in the fire protection sector is the presence of UL (Underwriters Laboratories) and FM (Factory Mutual) marks. These are not just logos; they represent a "Safety Covenant."

● UL Listing: Focuses on the structural integrity of the malleable iron pipe fitting under extreme conditions. UL 213 standards require the fitting to withstand a burst pressure test that is typically five times its rated working pressure (2.5 MPa).

● FM Approval: FM Global is the world’s largest commercial property insurer. Their standards focus on "Loss Prevention." An FM-approved fire fighting pipe fitting must prove it can survive the physical "hammer" of rapid water activation and the corrosive environment of stagnant "wet-pipe" systems.

Jianzhi’s dedication to these standards ensures that every galvanized pipe fitting used in a fire header has been validated by third-party laboratories. This certification lowers insurance premiums for building owners and provides the MEP engineer with verified data on the fitting's performance limits.

In a fire event, a pipe fitting often goes from room temperature to hundreds of degrees in minutes. When the sprinkler heads activate, cold water (often near 10°C) is pumped at high velocity into these scorching hot pipes. This creates a phenomenon known as "Thermal Shock."

A low-quality, brittle cast iron pipe fitting may crack instantly under this rapid contraction. However, as discussed in the metallurgy section, Jianzhi’s 96-hour annealing process produces a ferritic matrix with 10-12% elongation. This ductility allows the fire fighting pipe fitting to "flex" microscopically during the thermal transition. Instead of fracturing, the metal absorbs the stress, ensuring that water reaches the fire rather than flooding the floor through a broken joint.

Fire pumps are designed to deliver high volumes of water almost instantaneously. When these pumps kick in, they create a massive pressure surge, often referred to as "Water Hammer." This surge can momentarily spike the internal pressure well above the nominal 2.5 MPa rating.

Jianzhi’s "Heavy Type" design is a critical advantage here. The extra wall thickness at the "crotch" of our tees and the outer radius of our elbows provides the structural mass needed to dampen these energy waves. In a fire fighting pipe fitting application, mass equals safety. A thin-walled fitting might expand slightly under the surge, causing the threaded seal to weep or fail, whereas a Jianzhi heavy fitting maintains a rigid, hermetic seal.

Fire sprinkler systems often sit with the same water inside them for years. This stagnant environment is a breeding ground for internal corrosion. For these systems, the galvanized pipe fitting (specifically gi pipe fitting) is the standard choice.

The hot-dip galvanization process used by Jianzhi creates a zinc-iron alloy layer that is chemically bonded to the fitting. This is vital because if internal rust forms, it can flake off and clog the small orifices of the sprinkler heads. By ensuring a uniform, high-density zinc coating, we protect the pipe fitting from the inside out, guaranteeing that the waterway remains clear for decades.

In earthquake-prone regions, fire headers must remain functional even if the building structure moves. The combination of Jianzhi’s high elongation and CNC-machined threads ensures that the joints can withstand building shifts. The precision-cut 1:16 taper allows for deep thread engagement, which prevents the pipe from "pulling out" of the fire fighting pipe fitting during a seismic event.

When sourcing for fire protection, the decision matrix must prioritize:

1. Certification: Verified UL/FM stamps on every unit.

2. Ductility: 10-12% elongation to survive thermal shock.

3. Finish: High-quality gi pipe fitting to prevent internal clogging.

4. Geometry: "Heavy Type" mass to resist water hammer.

By specifying Jianzhi, you are not just buying a malleable iron pipe fitting; you are investing in a certified safety component engineered to perform in the most critical seconds of a building’s life.

In the procurement of malleable iron pipe fitting products, selecting the appropriate surface finish is a decision that balances cost-efficiency with long-term environmental resistance. The choice between a galvanized pipe fitting and a black pipe fitting (often referred to as an "oil-finished" fitting) is dictated by the chemical composition of the medium being transported and the corrosivity of the external atmosphere.

At Jianzhi, we provide both high-grade finishes, but we emphasize that the gi pipe fitting is the standard for durability in water-based and exposed industrial environments, while black fittings serve as the high-purity choice for gas and oil applications.

The galvanized pipe fitting is treated via a "Hot-Dip" process, where the iron is submerged in molten zinc at approximately 450°C. This creates a multi-layered metallurgical bond. Unlike simple paint or electro-plating, this zinc layer acts as a "sacrificial anode." Even if the surface is scratched during installation, the surrounding zinc will oxidize first, protecting the underlying iron from structural decay.

To estimate the service life of a gi pipe fitting in a specific environment, engineers use the following formula:

L = h / R

Where:

L = Expected life of the protective coating (years).

h = Thickness of the zinc coating (measured in micrometers, μm).

R = Annual corrosion rate of zinc in the local environment (μm/year).

In coastal or high-humidity industrial zones, the value of R is significantly higher. Jianzhi’s galvanized pipe fitting products typically feature a coating thickness (h) exceeding 70-80 μm, providing a service life that is decades longer than "Light Type" competitors who may only offer 30-40 μm of coverage.

A black pipe fitting is coated with a light anti-rust oil or a specialized lacquer. While it lacks the long-term atmospheric resistance of a gi pipe fitting, it is the preferred choice for specific media:

● Gas and Oil Lines: Zinc can react with certain fuels or oils, leading to "zinc soaps" that clog filters. Black fittings are inert in these environments.

● High-Temperature Steam: In systems exceeding 200°C, the zinc on a galvanized pipe fitting may begin to flake or lose its bond, whereas a black fitting remains stable.

● Indoor Controlled Climates: In dry, climate-controlled buildings, the extra cost of galvanization is unnecessary, and the black oil provides sufficient protection during the shipping and installation phase.

Feature | Galvanized (GI) Fitting | Black (Oil-Coated) Fitting |

Corrosion Resistance | Excellent (Sacrificial) | Low (Temporary) |

Best For | Potable Water, Fire Sprinklers, Outdoor | Gas, Fuel Oil, Steam, Indoor HVAC |

Cost | Higher (Zinc cost + Processing) | Lower |

Standard | ISO 1461 / ASTM A153 | Standard Anti-Rust Protocol |

By understanding the L = h / R logic, sourcing managers can justify the investment in a high-quality Jianzhi gi pipe fitting. In 2026, as sustainability and reduced maintenance become key project KPIs, the superior "h" value of our galvanization process ensures that the pipe fitting supply remains a permanent asset rather than a recurring expense.

In the fluid and gas handling industry, a malleable iron pipe fitting is only as reliable as its connection points. The thread is the mechanical "handshake" between the fitting and the pipe, and in a 2.5 MPa system, this handshake must be absolute. Precision threading is the difference between a system that remains hermetically sealed for fifty years and one that suffers from "slow leaks" that drain profit and compromise safety.

For the global sourcing manager, understanding threading is not just about choosing between sizes; it is about understanding the geometry of the seal. At Jianzhi, we have transitioned away from traditional manual lathe cutting to advanced CNC (Computer Numerical Control) machining to ensure that every pipe fitting we export meets the highest standards of global interconnectivity.

The most critical feature of a high-pressure malleable iron pipe fitting is the taper. Unlike standard bolt threads, which are straight, industrial pipe threads are cut on a 1:16 taper.

This 1:16 ratio is mathematically defined as a change in diameter of one unit for every sixteen units of length. This design creates an "interference fit." As the male pipe is screwed into the galvanized pipe fitting, the diameters converge until the metal surfaces are physically wedged together.

Taper Calculation:

If a manufacturer’s machinery is worn or poorly calibrated, this ratio might slip to 1:15 or 1:17. A deviation of even a fraction of a degree means the threads will "bottom out" (stop turning) before the metal-to-metal seal is fully engaged, or conversely, they will remain too loose, relying entirely on thread sealant to prevent leaks—a recipe for failure at 2.5 MPa.

One of the greatest hurdles in the global pipe fitting supply chain is the "Thread Divide." Depending on the project's location and industrial heritage, you will require one of two incompatible standards:

● NPT (National Pipe Taper): Predominant in North America. It features a 60° thread angle and flattened peaks and valleys (crests and roots).

● BSPT (British Standard Pipe Taper): Standard in Europe, Asia, and the Commonwealth. It features a 55° thread angle and rou

Because the angles differ (60° vs 55°), an NPT male will never properly seal in a BSPT gi pipe fitting. Jianzhi maintains dedicated CNC production lines for both standards. By using laser-calibrated master gauges, we ensure that our NPT fittings for the US market and our BSPT fittings for the Southeast Asian market provide the exact same level of leak-free performance.

In budget-grade malleable iron pipe fitting production, manual threading often leaves "chatter marks" or jagged edges. These microscopic irregularities create pathways for gas or water to escape.

Jianzhi’s CNC machining centers provide three distinct advantages:

1. Thread Smoothness: A smoother thread reduces friction during installation. This allows the plumber to reach the "tightness" required for a 2.5 MPa seal without using excessive torque that could split the fitting.

2. Axis Squareness: For a pipeline to run straight over long distances, the threads must be cut perfectly "square" to the fitting's body. If the thread is tilted by even 0.5 degrees, a ten-meter pipe run will be visibly off-line.

3. Clean Roots and Crests: CNC tools ensure that the valleys of the threads are free of debris and the peaks are sharp. This maximizes the contact surface area, which is vital for fire fighting pipe fitting systems where vibration resistance is mandatory.

Proper procurement specs should always check for "Effective Thread Length." This is the distance the pipe can actually screw into the pipe fitting. Jianzhi’s "Heavy Type" design allows for a deeper thread pocket. This ensures that more threads are engaged, spreading the mechanical load over a larger volume of metal. This is particularly important for gi pipe fitting applications in high-vibration environments, such as near industrial pumps or compressors, where shallow threads would eventually "fret" and leak.

By prioritizing CNC precision and strict adherence to the 1:16 taper, Jianzhi removes the guesswork from pipeline assembly. For the international buyer, this precision translates into faster installation times, fewer "call-backs" for leaks, and a system that stands the test of time.

In the global procurement of malleable iron pipe fitting products, the most critical physical attribute is often the most overlooked: wall thickness. In a market flooded with "Light Type" alternatives designed to save on raw material costs, the "Heavy Type" philosophy adopted by Jianzhi represents a fundamental commitment to mechanical survival. For a system rated at 2.5 MPa (363 PSI), structural integrity is not a luxury—it is a mathematical necessity.

When sourcing a pipe fitting, the weight of the unit is a direct proxy for its safety margin. A "Heavy Type" fitting isn't just heavier in the hand; it is engineered to distribute internal and external stresses more effectively, ensuring the long-term stability of the entire pipeline.

To understand why wall thickness is the primary determinant of quality, we must examine the Hoop Stress (also known as tangential stress). When a fluid or gas is pressurized to 2.5 MPa, it exerts an outward force against the interior walls of the malleable iron pipe fitting.

The mechanical stress experienced by the metal is calculated using the following formula:

Sh = (P · d) / (2 · t)

Where:

Sh = Hoop Stress (the internal tension within the metal matrix).

P = Internal pressure (2.5 MPa).

d = Internal diameter of the fitting.

t = Wall thickness.

From this equation, it is clear that the stress (Sh) is inversely proportional to the wall thickness (t). If a manufacturer reduces the wall thickness to save costs, the stress on the remaining metal increases exponentially. By maintaining a thicker wall, Jianzhi’s gi pipe fitting ensures that the actual stress remains far below the yield point of the iron, providing a massive safety buffer against pressure spikes and water hammer.

A pipe fitting must withstand more than just internal pressure; it must survive the installation process. Because a malleable iron pipe fitting uses a tapered thread (1:16 ratio), the male pipe acts as a wedge. As the installer tightens the joint to ensure a leak-proof seal, they exert a massive radial expansion force on the female hub of the fitting.

"Light Type" fittings are prone to "longitudinal splitting"—a failure where the hub of the fitting cracks from the face downward during tightening. Jianzhi’s "Heavy Type" fire fighting pipe fitting features reinforced bands and thicker walls at the threading zone. This extra mass acts as a structural "hoop" that contains the expansion force, allowing for high-torque tightening without the risk of structural failure.

Structural integrity must be measured over the lifecycle of the building, not just on the day of commissioning. All pipelines experience internal erosion (from high-velocity fluid) and potential corrosion.

A galvanized pipe fitting provides a chemical barrier, but the wall thickness provides the physical barrier. If a fitting with a 4mm wall loses 0.5mm to internal erosion over twenty years, it still retains 3.5mm of load-bearing iron.

A thin-walled fitting losing the same amount of material may reach its "critical thinness," leading to a catastrophic burst. For procurement managers, the Jianzhi "Heavy Type" design provides a "Corrosion Allowance" that guarantees the system's 50-year design life.

In industrial settings, pumps and compressors create constant mechanical vibration. These vibrations can cause "fatigue cracking" in rigid materials over time. Mass is a natural dampener of vibration. A heavier malleable iron pipe fitting has a higher "damping capacity" than a thin-walled one. By specifying Jianzhi’s "Heavy Type" products, the entire pipe fitting network becomes more stable, reducing the risk of fatigue-related leaks at the thread roots—the most common site of failure in Class 150 systems.

Feature | Jianzhi "Heavy Type" | Generic "Light Type" |

Material Usage | 15-25% More Iron | Minimum Possible |

Hoop Stress (Sh) | Low (Safer) | High (Risk of Burst) |

Torque Tolerance | High (Resists Splitting) | Low (Prone to Cracking) |

Service Life | 50+ Years | 15-20 Years (Variable) |

Application | Critical/Industrial 2.5 MPa | Light Residential Only |

By prioritizing the math of Sh = (P · d) / (2 · t), Jianzhi ensures that every gi pipe fitting we supply is a permanent structural asset. In 2026, where infrastructure reliability is a non-negotiable KPI, the "Heavy Type" fitting remains the only logical choice for professional sourcing.

Efficiently moving a malleable iron pipe fitting from the foundry floor to a construction site halfway across the world requires more than just manufacturing prowess; it requires a sophisticated logistical framework. For a global sourcing manager, the quality of the "Supply Chain" is just as important as the quality of the iron. In the 2026 market, where lead times and "Zero-Defect" delivery are key performance indicators, Jianzhi has optimized its logistics to ensure that our pipe fitting products arrive on time, in perfect condition, and ready for immediate installation in 2.5 MPa systems.

Most manufacturers in the pipe fitting industry rely on "Batch Sampling"—testing only a small percentage of a production run. This statistically allows for a certain number of defective units to reach the customer. Jianzhi has eliminated this risk by implementing a 100% air-under-water testing protocol.

Every single malleable iron pipe fitting, whether it is a black elbow or a gi pipe fitting, is pressurized with high-pressure air and submerged in water. If a single bubble appears, the fitting is rejected. This rigorous quality gate ensures that when a container of fire fighting pipe fitting products reaches a project site, the contractor can install them with 100% confidence, eliminating the massive labor costs associated with "on-site rework" due to leaks.

International shipping involves high humidity, temperature fluctuations, and mechanical shocks. Jianzhi utilizes reinforced, double-walled corrugated cartons and high-strength plastic woven bags to prevent damage. For large-scale orders of galvanized pipe fitting products, we use standardized wooden pallets that are fumigated and shrink-wrapped to prevent shifting during sea freight.

Our packaging also includes clear, multilingual labeling and QR codes. This allows warehouse managers to quickly scan and track inventory, ensuring that the right gi pipe fitting sizes are directed to the right project phases. This digital integration reduces "Logistical Friction" and speeds up the unloading process at the port of destination.

In the fast-paced world of MEP (Mechanical, Electrical, and Plumbing) contracting, a delay in the delivery of a malleable iron pipe fitting can stall an entire skyscraper project. Jianzhi maintains a massive buffer stock of standard sizes (1/2" to 4") in our centralized warehouses.

By leveraging automated inventory management, we can typically achieve a lead time of 2-4 weeks for standard orders, significantly faster than the industry average of 8-12 weeks. For custom fire fighting pipe fitting specifications, our integrated production planning system allows us to "fast-track" manufacturing cycles without compromising the critical 96-hour annealing process.

By choosing Jianzhi, sourcing managers gain more than just a pipe fitting; they gain a logistical partner dedicated to:

Zero Rework: 100% leak testing means no on-site failures.

Damage Prevention: Industrial-grade packaging for harsh maritime transit.

Speed to Market: Optimized lead times that keep project schedules on track.

In 2026, as global supply chains become more complex, Jianzhi’s commitment to logistical excellence ensures that your malleable iron pipe fitting supply remains the most stable link in your infrastructure project.

To streamline the procurement process, we have compiled the most critical questions asked by global sourcing managers when evaluating a malleable iron pipe fitting supplier. These answers are based on the technical standards and logistical realities of the 2026 industrial market.

Q1: How does Jianzhi maintain 100% airtightness in Class 150 systems?

A: Unlike many foundries that use "batch sampling," Jianzhi implements a 100% air-under-water test for every single pipe fitting produced. Each unit is pressurized with air and submerged; any leakage—even a single bubble—results in immediate rejection. This ensures that every malleable iron pipe fitting delivered to your site is ready for a 2.5 MPa working pressure without the risk of on-site rework.

Q2: Is there a significant difference between "Light Type" and Jianzhi "Heavy Type" fittings?

A: Yes, the difference is structural. Based on the Hoop Stress formula, Sh = (P · d) / (2 · t), a thinner wall (t) increases the internal stress on the metal. Jianzhi "Heavy Type" fittings contain 15% to 25% more iron than generic alternatives. This extra mass provides a critical "Corrosion Allowance" and prevents the fitting from splitting when high torque is applied during the installation of a fire fighting pipe fitting system.

Q3: Why is 96-hour annealing better than the industry-standard 72 hours?

A: Annealing is a time-temperature transformation. The extra 24 hours in Jianzhi’s computer-controlled furnaces ensures the complete conversion of brittle carbides into a ferritic matrix. This results in 10-12% elongation, providing the ductility needed for a gi pipe fitting to survive seismic shifts and thermal expansion without cracking.

Q4: Which thread standard should I specify for my international project?

A: This depends on your region’s plumbing code. Generally, NPT (60° angle) is required for North American and Oil & Gas projects. BSPT (55° angle) is the standard for Europe, Asia, and the Commonwealth. Jianzhi uses CNC machining to ensure a precise 1:16 taper for both standards, ensuring leak-free interconnectivity regardless of the project location.

Q5: Can I use a galvanized pipe fitting for high-temperature steam lines?

A: We do not recommend it. For steam systems exceeding 200°C, the zinc coating on a galvanized pipe fitting can lose its bond and flake off, potentially clogging valves. For steam and high-purity oil lines, a black pipe fitting (oil-coated) is the superior choice. For water and fire protection, however, the gi pipe fitting is essential for its sacrificial corrosion protection.

Q6: What certifications are mandatory for a fire fighting pipe fitting supply?

A: For life-safety systems, you should only source fittings that are UL Listed and FM Approved. These certifications prove the malleable iron pipe fitting has passed rigorous burst-pressure and vibration tests. All Jianzhi fire-protection fittings carry these marks, satisfying both building inspectors and insurance underwriters.

Q7: How do you protect galvanized fittings from "White Rust" during sea transit?

A: "White Rust" occurs when new zinc is exposed to moisture and lack of airflow. Jianzhi prevents this through high-quality hot-dip galvanization (ensuring a high h value in the L=h/R formula) and by using export-grade, moisture-resistant packaging and shrink-wrapped pallets to isolate the gi pipe fitting supply from humid maritime air.

Q8: What are the typical lead times for a container-load of fittings?

A: Due to our high-volume vertical molding lines and automated warehousing, Jianzhi maintains a large buffer of standard sizes. While the industry average is 8-12 weeks, we typically fulfill standard malleable iron pipe fitting orders within 2-4 weeks, ensuring your project stays on schedule.

The successful procurement of a malleable iron pipe fitting supply is a multifaceted challenge that demands a balance of metallurgical science, geometric precision, and logistical reliability. As we have explored in this guide, the transition from a "commodity" mindset to a "technical" mindset is essential for the integrity of modern 2.5 MPa infrastructure. By prioritizing the "Heavy Type" design, the 96-hour annealing cycle, and 100% air-testing, Jianzhi has set a global benchmark that ensures every pipe fitting we produce is not just a connector, but a high-performance safety component.

For the global sourcing manager, the "Jianzhi Solution" represents a reduction in long-term risk. Whether you are specifying a fire fighting pipe fitting for a high-rise safety network or a gi pipe fitting for an industrial water grid, the principles of material honesty remain the same. Mass, ductility, and thread accuracy are the three pillars of a leak-free system. By adhering to the formulas of Hoop Stress (Sh = (P·d) / (2·t)) and Coating Life (L = h / R), procurement teams can mathematically justify the selection of premium malleable iron pipe fitting products as the most cost-effective decision over the project’s lifecycle.

To further support your engineering and sourcing efforts, we recommend consulting the following international standards and Jianzhi technical resources:

1. ISO 49:1994 – Malleable cast iron fittings threaded to ISO 7-1. This is the primary international reference for "Design Symbol A" fittings used by Jianzhi. https://www.iso.org/standard/4462.html

2. EN 10242:1994 – Threaded pipe fittings in malleable cast iron. The European benchmark for galvanized pipe fitting quality and protective coatings. https://standards.iteh.ai/catalog/standards/cen/en-10242-1994

3. ASME B16.3-2021 – Malleable Iron Threaded Fittings: Classes 150 and 300. The American standard validating the 2.5 MPa working pressure for industrial applications. https://www.asme.org/codes-standards/b16-3

4. UL 213 & FM 1112 – The critical safety standards for any fire fighting pipe fitting. These certifications ensure the material can survive the thermal and hydraulic shocks of emergency deployment. https://www.fmapprovals.com/approval-standard-1112

5. ISO 7-1 & ASME B1.20.1 – The definitive guides for BSPT and NPT threading, establishing the 1:16 taper geometry necessary for hermetic seals. https://www.iso.org/standard/4437.html

6. Jianzhi Technical Support Archive – Our proprietary repository for annealing logs, 100% air-testing reports, and material traceability certificates. https://www.jianzhipipefitting.com/technical-support/ https://www.malleableiron-pipefitting.com/

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania