Dec. 15, 2025

In the modern industrial landscape, "compliance" is the bedrock of risk management. This paper analyzes the technical certifications—including UL, FM, CE, and ISO—that govern the production of black pipe fitting and galvanized solutions at Jianzhi. By examining the relationship between "Heavy Type" design and pressure-temperature performance, we demonstrate how Jianzhi’s 100% testing protocol creates a "Zero-Defect" environment. This guide serves as an essential reference for procurement managers and MEP (Mechanical, Electrical, and Plumbing) engineers seeking high-reliability piping joints.

Safety Benchmarks: Jianzhi holds elite UL Listing and FM Approval, essential for global fire protection systems.

Pressure Resilience: Superior performance in both Class 150 and Class 300 categories with a verified 4:1 safety factor.

Zero-Leak Guarantee: Achievement of a 0% failure rate through 100% air-tightness testing at 0.6 MPa.

Technical Integrity: Use of high-precision CNC machining for both BSPT and NPT threading standards to ensure global interoperability.

1.Abstract & Key Takeaways

2. Table of Contents

3. The Global Standardization Hierarchy (ISO, ASME, EN)

4. Pressure Ratings & Thermal Dynamics

5. The "Big Two" for Safety: UL Listing and FM Approval

6. "Heavy Type" Design & Manufacturing Excellence

7. 100% Quality Assurance & Testing Protocols

8. Material Performance & Traceability (12% Elongation)

9. Frequently Asked Questions (FAQ)

10. References (Technical Bibliography)

In the global fluid conveyance industry, standardization is the bridge between a manufacturer in China and an infrastructure project in the United Kingdom or Brazil. For Hebei Jianzhi Casting Group, adhering to international standards is not merely a box-ticking exercise—it is a commitment to geometric and metallurgical interoperability. Without these strict hierarchies, a black pipe fitting would be a localized commodity rather than a global engineering solution.

The International Organization for Standardization provides the "Common Language" for the piping industry. Jianzhi’s primary compliance is with ISO 49, which specifies the requirements for the design and performance of threaded fittings in malleable cast iron. This standard governs everything from the material grade to the pressure testing protocols.

Coupled with ISO 49 is the critical ISO 7-1, which defines the BSPT (British Standard Pipe Taper). Because Jianzhi exports to over 100 countries, mastering the 1:16 taper and the 55° thread angle required by ISO 7-1 is paramount. Our CNC machining centers are calibrated to ensure that the "gauge length"— the distance a pipe can be screwed in by hand before requiring a wrench—is perfectly consistent. This prevents the common field issue of "bottoming out" threads, which often leads to leaks in high-pressure gas systems.

For the North American market, the American Society of Mechanical Engineers (ASME) sets the gold standard. ASME B16.3 specifically covers malleable iron pipe fitting products for Classes 150 and 300.

A key distinction in the ASME hierarchy is the requirement for NPT (National Pipe Thread), which utilizes a 60° thread angle. Jianzhi’s "Heavy Type" philosophy is particularly relevant here; ASME standards demand specific wall thicknesses to handle the high-torque installation methods common in US construction. By meeting B16.3, Jianzhi ensures that its cast iron pipe fitting range can safely handle the pressures of North American natural gas distribution and industrial steam lines.

In Europe, the EN 10242 standard is the ultimate arbiter of quality. This standard categorizes fittings into "Design Symbols" based on their material properties and threading precision.

Design Symbol A: This is the highest classification. It requires the use of high-grade ferritic malleable iron and high-precision tapered threads.

Jianzhi’s Compliance: Every Jianzhi fitting exported to the EU is manufactured to Design Symbol A.

This compliance ensures that the black pipe fitting is not only strong enough to handle internal pressure but also ductile enough to withstand the mechanical stresses of thermal expansion and contraction, which are frequent in European district heating systems.

While dimensions are governed by the standards above, the "soul" of the fitting—the metal itself—is governed by ASTM A197. This standard specifies the chemical and tensile requirements for "Cupola Malleable Iron." Jianzhi utilizes electric induction furnaces to achieve a level of purity that often exceeds ASTM A197 requirements, ensuring that the "temper carbon" nodules are evenly distributed throughout the iron matrix.

By navigating this complex standardization hierarchy, Jianzhi provides a universal solution. Whether a project requires the 55° rounded threads of a BSPT system or the 60° truncated threads of an NPT system, our facility produces a certified, traceable, and reliable joint. For the engineer, this hierarchy is the guarantee that the malleable iron pipe fitting they specify today will perform exactly as expected for the next fifty years.

In the realm of mechanical engineering, the ability of a malleable iron pipe fitting to contain fluid or gas is not a fixed attribute; it is a dynamic variable influenced by the interplay of internal pressure and external temperature. Understanding Section 4 is critical for any engineer designing high-capacity systems, as it defines the safe operational boundaries that prevent catastrophic failure.

Pressure ratings for black pipe fitting products are generally categorized into Class 150 and Class 300. These designations do not represent a simple "pounds per square inch" (PSI) limit at all conditions. Instead, they refer to a pressure-temperature rating schedule.

A Class 150 Jianzhi fitting is engineered for "Standard Duty." Under ambient conditions -20℃ to 40℃, these fittings can safely manage pressures up to 2.0 MPa (300 PSI). However, Class 300 fittings are designed for "Heavy Duty" environments—such as deep-well oil extraction or high-pressure steam headers—capable of withstanding up to 10.3 MPa (1,500 PSI) at ambient temperatures.

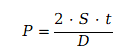

Jianzhi’s "Heavy Type" design ensures that the actual burst pressure is significantly higher than these rated values. We utilize the Barlow Formula to calculate the theoretical burst point of our fittings:

By maintaining a thicker nominal wall (t) than the minimum industry requirements, Jianzhi provides an inherent "Safety Factor of 4." This means a fitting rated for 300 PSI is typically tested to withstand a burst pressure of 1,200 PSI before structural compromise occurs.

The most critical concept in thermal dynamics is derating. As the temperature of the fluid increases, the tensile strength of the iron slightly decreases, and the internal stress on the fitting walls increases due to thermal expansion.

For instance, a Jianzhi cast iron pipe fitting rated at 2.0 MPa at 66℃ must be "derated" to 1.3 MPa if the operating temperature reaches 200℃. This is why malleable iron is superior to ductile iron or plastic in steam applications; it retains a higher percentage of its structural integrity at elevated temperatures.

Operating Temp (°C) | Class 150 Max Pressure (MPa) | Class 300 Max Pressure (MPa) |

-20 to 66 | 2.07 | 10.34 |

150 | 1.58 | 7.31 |

230 | 1.21 | 5.03 |

Thermal dynamics also involves the physical expansion of the metal. In a long piping run, the pipe and the malleable iron pipe fitting will expand and contract as the system cycles on and off.

Because Jianzhi fittings are manufactured from high-grade ferritic iron, their coefficient of thermal expansion is closely matched to that of the carbon steel pipes they connect. This matching is vital. If the fitting and the pipe expanded at different rates, the threads would experience "cyclic loading," eventually leading to microscopic gaps and "weeping" leaks. Jianzhi’s strict metallurgical control ensures that the fitting acts as a monolithic part of the pipe run, maintaining a gas-tight seal even after thousands of thermal cycles.

Dynamic pressure spikes, known as Water Hammer, occur when a valve is closed rapidly, sending a shockwave through the system. In these moments, the internal pressure can momentarily triple.

The "malleable" nature of our iron—specifically the temper carbon nodules—allows the fitting to absorb a portion of this kinetic energy through microscopic elastic deformation. A brittle, non-certified cast iron pipe fitting would shatter under such a surge. Jianzhi fittings are specifically tested to ensure that the combination of "Heavy Type" wall thickness and material ductility can survive these high-velocity pressure transients.

In conclusion, the pressure rating of a Jianzhi black pipe fitting is a promise backed by mathematical modeling and thermal stress analysis. By understanding the derating tables and the advantages of our "Heavy Type" geometry, engineers can design systems with total confidence, knowing that Jianzhi provides the necessary safety margins to handle both steady-state pressure and the unpredictable dynamics of temperature fluctuations.

In the global landscape of fire protection and high-stakes industrial infrastructure, two acronyms stand above all others: UL and FM. For a malleable iron pipe fitting to be installed in a high-rise fire sprinkler system or a volatile chemical refinery, it must carry these certifications. At Hebei Jianzhi Casting Group, our commitment to these standards is not merely about market access; it is about the fundamental moral responsibility of manufacturing life-saving components.

UL (Underwriters Laboratories) is a global safety science leader. For a Jianzhi black pipe fitting to earn a UL Listing, it must undergo a battery of tests that simulate the most extreme conditions a piping system might encounter.

The core of UL testing for pipe fittings revolves around Burst Pressure and Tightness. UL standards often require that a fitting withstand a hydrostatic pressure of at least five times its rated working pressure without leaking or rupturing. For a standard 300 PSI fire protection system, this means the Jianzhi fitting is tested to 1,500 PSI. Furthermore, UL evaluates the precision of the threads. A UL-certified cast iron pipe fitting must demonstrate a perfect thread profile to ensure that, even under the vibration of high-velocity water flow, the joint remains immovable and leak-proof.

While UL focuses on general safety, FM (Factory Mutual) Approvals is an international leader in third-party testing specifically for property loss prevention. FM Global is one of the world's largest commercial insurers, and their research-based testing is designed to ensure that products will perform reliably to prevent catastrophic property damage.

For malleable iron pipe fitting products, FM Approval is particularly rigorous regarding Mechanical Strength and Corrosion Resistance. FM engineers examine the metallurgical consistency of our iron. They ensure that the "temper carbon" nodules—the result of our 96-hour annealing process—are distributed in a way that provides maximum ductility. In the event of an earthquake or a structural collapse during a fire, an FM-approved Jianzhi fitting is designed to bend and deform rather than shatter, maintaining the flow of water to critical fire suppression heads.

One of the most intense tests for UL/FM certification is the Thermal Shock Test. In a real-world fire scenario, piping can reach hundreds of degrees Celsius. When the fire sprinkler system activates, cold water suddenly surges through the scorching metal. This rapid temperature delta can cause inferior cast iron pipe fitting products to crack due to sudden contraction.

Because Jianzhi utilizes a "Heavy Type" design with a refined ferritic matrix, our fittings possess the thermal resilience to survive this shock. UL and FM certifications serve as the independent verification that Jianzhi fittings will not fail at the exact moment they are needed most.

From a procurement and insurance perspective, using UL-listed and FM-approved fittings is a strategic financial decision.

Liability Mitigation: MEP engineers specify Jianzhi because it shifts the technical risk to an internationally verified standard.

Lower Premiums: Many industrial insurers will not provide coverage, or will charge significantly higher premiums, for facilities that utilize uncertified piping components.

Building Codes: In most developed jurisdictions, fire codes mandate the use of UL/FM-certified fittings for all fire suppression systems.

Maintaining these certifications requires continuous audits. UL and FM representatives regularly visit our 400,000sqm facility to inspect our melt logs, our 100% air-under-water testing stations, and our spectral analysis data. By consistently passing these audits, Jianzhi proves that every black pipe fitting leaving our line is identical in quality to the one tested in the UL/FM laboratories.

In summary, the "Big Two" certifications are the ultimate proof of performance. They transform a simple iron casting into a sophisticated safety device. When you see the UL and FM marks on a Jianzhi malleable iron pipe fitting, you are looking at a product that has been engineered to protect lives, safeguard property, and endure the most hostile environments on earth.

In the global market for malleable iron pipe fitting products, there is a stark divide between "commodity" fittings and "engineered" fittings. At Hebei Jianzhi Casting Group, we have built our 40-year reputation on the "Heavy Type" philosophy. This design mandate is not merely about using more metal; it is an uncompromising approach to manufacturing excellence that ensures our black pipe fitting products remain the gold standard for durability and safety in 2025.

In an effort to lower costs, many manufacturers have moved toward "light-type" fittings—reducing wall thickness and narrowing the reinforcement bands. While these fittings may meet the bare minimum of standard requirements, they offer zero margin for error.

Jianzhi’s "Heavy Type" fittings are engineered to be 15% to 20% heavier than the industry average. This strategic addition of material serves three critical engineering purposes:

● Corrosion Allowance: The extra wall thickness provides a longer service life in environments where oxidation is a constant threat.

● Mechanical Strength: A thicker body can withstand higher installation torque and the intense pressure spikes caused by "water hammer."

● Reinforced Junctions: The "crotch" of our Tees and the entry points of our Elbows feature extra metal reinforcement. This prevents the "splitting" that commonly occurs in light-type fittings when a male pipe is over-tightened during installation.

Manufacturing excellence begins in the mold. Jianzhi utilizes the Disamatic (Denmark) high-pressure vertical molding system. Unlike traditional sand casting, which can be inconsistent, the Disamatic system uses hydraulic pressure to create ultra-dense sand molds.

This high-pressure molding ensures that the external geometry of every cast iron pipe fitting is perfectly consistent. More importantly, it prevents internal "voids" or "gas holes." In a standard sand casting, tiny air bubbles can become trapped in the molten iron, creating a path for leaks. The Disamatic system, combined with our precision-engineered sand cores, ensures a dense molecular structure that is naturally gas-tight.

The soul of a malleable iron pipe fitting is its heat treatment. When iron is first cast, it is "White Iron"—as brittle as glass. To become "Malleable Iron," it must undergo graphitization in an annealing kiln.

While many competitors shorten their annealing cycles to 48 or 60 hours to save energy, Jianzhi maintains a 96-hour cycle in our massive tunnel kilns. This long-duration, controlled heating and cooling allows the carbon flakes to fully transform into spherical "temper carbon" nodules. This is the difference between a fitting that shatters under stress and one that bends. Our 96-hour process is why Jianzhi fittings consistently achieve a 10–12% elongation rate, providing an enormous safety buffer for installers.

Excellence at Jianzhi is supported by our massive scale. Our 400,000-square-meter facility is a vertically integrated ecosystem. We do not outsource critical steps.

In-House Tooling: We design and manufacture our own molds using CNC machining centers to ensure 0.01mm accuracy.

Automated Threading: Our multi-spindle threading machines ensure that the BSPT or NPT threads are perfectly concentric to the fitting body.

Spectral Analysis: Before any iron is poured, we use digital spectrographs to verify the chemical "recipe" of the melt.

Choosing a Jianzhi "Heavy Type" fitting is an investment in system longevity. By combining superior material mass with world-class Danish molding technology and an exhaustive annealing process, we produce a black pipe fitting that is over-engineered for its environment. In the world of industrial piping, "good enough" is a risk. Jianzhi’s manufacturing excellence ensures that our customers never have to take that risk.

In the competitive landscape of industrial manufacturing, many companies rely on "Statistical Quality Control"—a method where only a small percentage (often less than 1%) of a batch is tested. At Hebei Jianzhi Casting Group, we recognize that for a high-pressure gas line or a fire suppression system, a 1% failure rate is not just a statistic; it is a potential catastrophe. To eliminate this risk, Jianzhi has implemented a 100% Quality Assurance (QA) and Testing Protocol. This ensures that every single malleable iron pipe fitting leaving our 400,000sqm facility is a verified "Zero-Defect" component.

The most critical phase of our QA process is the air-under-water leak test. While many factories skip this for smaller or "light-type" fittings, Jianzhi mandates it for every SKU in our catalog.

Each black pipe fitting is sealed at its openings and injected with high-pressure compressed air (typically 0.6 MPa / 87 PSI). The fitting is then fully submerged in a clear water tank. Our inspectors look for the slightest sign of a bubble. If a single bubble escapes—indicating a microscopic pinhole, a sand hole from casting, or a hairline fracture from the annealing process—the fitting is immediately rejected and sent back to the furnace to be melted down. This 100% manual and automated inspection is the primary reason Jianzhi is the preferred brand for natural gas distribution networks where "leak-proof" is the only acceptable standard.

Quality at Jianzhi starts before the iron is even poured. We utilize advanced Optical Emission Spectrometers (OES) to analyze the chemical composition of every "melt."

For a cast iron pipe fitting to become truly malleable, the ratios of Carbon, Silicon, Manganese, Sulfur, and Phosphorus must be exact. If the silicon content is too high, the fitting becomes brittle; if the carbon is too low, the iron will not flow into the mold correctly. By testing the molten iron in real-time, our technical engineers can make micro-adjustments to the chemistry, ensuring that the "recipe" for our high-grade ferritic iron remains consistent batch after batch.

A fitting can be structurally sound but functionally useless if the threads are not perfect. Jianzhi utilizes multi-spindle CNC threading machines that provide a level of accuracy impossible to achieve with manual lathes.

To verify this, we utilize a rigorous gauging protocol using "Go/No-Go" master gauges.

Thread Taper: We verify the 1:16 taper angle for both BSPT and NPT standards.

Thread Depth: Ensuring the pipe can be engaged to the correct "hand-tight" length before wrenching.

Alignment (Squareness): We test the axis of the threads against the axis of the fitting body. A misalignment of even 1 degree can cause a 10-meter pipe run to be off-center by several centimeters. Jianzhi’s "Squareness" testing ensures that installers never have to "force" a connection.

Beyond the non-destructive air tests, Jianzhi conducts destructive testing on random samples from every production shift to verify the physical limits of the material.

Burst Pressure Testing: We pressurize fittings until they fail. A Jianzhi Class 150 fitting, rated for 300 PSI, is expected to withstand over 1,200 PSI before bursting, validating our 4:1 safety factor.

Flattening and Crush Tests: This ensures the 96-hour annealing was successful. A sample fitting is crushed in a hydraulic press; it must deform and flatten significantly without cracking, proving its superior ductility.

Excellence is not just about machines; it is about the 4,000 employees who operate them. Jianzhi’s QA protocol includes a unique "internal incentive system" where workers are rewarded for identifying defects early in the production line. This turns every employee into an inspector.

In summary, Jianzhi’s 100% testing protocol is an investment in our customers' peace of mind. When an engineer specifies a Jianzhi malleable iron pipe fitting, they are utilizing a product that has been chemically analyzed, air-tested under water, and geometrically verified to the highest international standards. In the world of industrial piping, this level of QA is the difference between a system that lasts for decades and one that fails in months.

In the final technical analysis of Jianzhi’s engineering standards, we move from the external geometry of the fitting to its internal molecular performance. For a malleable iron pipe fitting, the true measure of quality is found in its ability to endure mechanical stress, vibration, and environmental degradation over decades. At Hebei Jianzhi Casting Group, we define this performance through two critical pillars: a industry-leading 12% elongation rate and a rigorous traceability system backed by international certification.

Elongation is a physical property that measures the degree to which a metal can be stretched or deformed before it fractures. In the world of cast iron pipe fitting products, elongation is the primary indicator of ductility. While standard malleable iron specifications (such as those found in ISO 49 or ASTM A197) often require a minimum elongation of only 5% to 6%, Jianzhi consistently achieves between 10% and 12%.

In a laboratory, elongation is a number on a chart. In the real world, it is a life-saving safety margin.

Seismic Resilience: In earthquake-prone regions, building foundations shift. A piping system with low ductility will crack at the joints under the strain of structural movement. Jianzhi’s 12% elongation allows the black pipe fitting to "give" and slightly deform without losing its seal, preventing gas leaks or fire system failures during seismic events.

Vibration Damping: In industrial pump rooms, pipes are subject to constant high-frequency vibration. Brittle iron develops "fatigue cracks" over time. The superior ductility of Jianzhi iron acts as a natural shock absorber, dissipating vibrational energy through the ferritic matrix.

Thermal Expansion Stress: In steam and HVAC systems, pipes expand and contract with every heating cycle. High elongation ensures that the fitting can manage the resulting mechanical tension without the threads stripping or the body of the tee or elbow fracturing.

This high level of performance is the direct result of our 96-hour annealing process. By heating the white iron castings to 950℃ and cooling them at a meticulously controlled rate of 3℃ to 5℃ per hour, we ensure that every molecule of iron carbide is dissociated. This creates a matrix of soft, ductile ferrite interspersed with small, spherical "temper carbon" (graphite) nodules. These nodules act as internal "crack arrestors," preventing any microscopic flaws from propagating into a full fracture.

A secondary factor in our material performance is the exclusion of "Pearlite." In lower-quality malleable iron pipe fitting products, the cooling process is rushed, leaving a "Pearlitic" structure which is harder but significantly more brittle. Jianzhi’s metallurgy is strictly "Ferritic," resulting in a Brinell hardness of less than 150 HB.

This low hardness is not a sign of weakness; rather, it indicates superior machinability. When an installer threads a pipe into a Jianzhi fitting, the metal "seats" perfectly. The threads are cut cleaner and smoother by our CNC machines, which reduces the friction and heat generated during installation, further preserving the integrity of the joint.

In modern infrastructure projects—from oil refineries in the Middle East to high-rise towers in New York—engineers require more than just a product; they require proof. Traceability is the ability to track a specific black pipe fitting from the end-user's hands back to the specific furnace "melt" and the day it was cast.

Jianzhi provides full documentation in accordance with the EN 10204 3.1 standard. This is a "Type 3.1" inspection certificate, which is issued by a department independent of the manufacturing unit and is validated by an authorized representative of the manufacturer.

Our MTCs include:

Chemical Composition: Percentages of Carbon, Silicon, Manganese, Sulfur, and Phosphorus.

Mechanical Properties: Actual results of the tensile strength and elongation tests for that specific batch.

Pressure Test Confirmation: Verification that the batch passed the 100% air-under-water test.

Every box of Jianzhi fittings, and often the fittings themselves, carries a unique batch code. In the rare event of a field issue, this code allows our technical engineers to pull the historical records of the spectral analysis, the annealing kiln temperature logs, and the molding pressure data from that specific day. This level of accountability is what has earned Jianzhi the status of a "Premier Supplier" for national gas grids and international fire protection contractors.

Traceability begins with raw material control. Unlike older foundries that use "Cupola" furnaces—which are difficult to control and prone to chemical fluctuations—Jianzhi utilizes Electric Induction Furnaces.

These furnaces allow for ultra-precise temperature control and the ability to "tune" the chemistry of the iron with surgical precision. Because we control the melt so tightly, our material performance remains uniform across millions of units. When an engineer specifies Jianzhi, they are getting a product with a predictable molecular behavior, ensuring that the cast iron pipe fitting will behave exactly as the CAD models and stress simulations predict.

To illustrate the value of 12% elongation and traceability, consider the following data:

Metric | Industry Standard (Generic) | Jianzhi "Heavy Type" |

Elongation Rate | 5% - 6% | 10% - 12% |

Tensile Strength | 300 MPa | 330 - 350 MPa |

Testing | Batch Sampling (1 in 100) | 100% Individual Testing |

Documentation | Generic "Statement of Conformity" | Full EN 10204 3.1 MTC |

Machinability | High Hardness (Tools dull quickly) | Low Hardness (Easy threading) |

The combination of 12% elongation and global traceability creates a product that is not just a commodity, but a strategic asset. Jianzhi’s malleable iron pipe fitting line offers the ductility to survive extreme mechanical stress and the documentation to satisfy the most rigorous legal and safety audits. In 2025, as infrastructure safety becomes more scrutinized than ever, the Jianzhi "Material Advantage" provides the transparency and performance that modern engineers demand.

Q1: What is the technical difference between "Black" and "Galvanized" pipe fittings?

A: The difference lies in the surface treatment and the intended application. A black pipe fitting from Jianzhi is coated with a proprietary anti-rust oil. It is primarily used for gas lines, steam systems, and oil transport where the presence of zinc (found in galvanized coatings) could flake off and clog sensitive valves or burners. Galvanized fittings, on the other hand, are hot-dipped in a zinc bath to provide high corrosion resistance for potable water systems and outdoor environments. Metallurgically, the iron body is identical; only the protective barrier differs to suit chemical compatibility.

Q2: Why is the 96-hour annealing cycle considered the industry benchmark?

A: Annealing is the thermal process that converts brittle "White Iron" into "Malleable Iron." Many manufacturers reduce this cycle to 48 or 60 hours to save on electricity and fuel costs. However, a shortened cycle often leads to "incomplete graphitization," where microscopic clusters of iron carbide remain in the metal. This results in "hard spots" that can shatter under stress. Jianzhi’s 96-hour cycle ensures a total transformation into a ferritic matrix with temper carbon nodules. This is the only way to consistently achieve the 12% elongation rate required for seismic-grade safety.

Q3: Can Jianzhi fittings be used in high-pressure hydraulic systems?

A: While malleable iron is exceptionally strong, it is generally rated for Class 150 (300 PSI) or Class 300 (1,500 PSI) applications. For hydraulic systems exceeding 3,000 PSI, forged steel fittings are usually required. However, for most industrial hydraulic return lines and medium-pressure systems, Jianzhi’s Class 300 malleable iron pipe fitting is an excellent, cost-effective choice that offers superior vibration damping compared to rigid steel.

Q4: How does Jianzhi ensure thread compatibility between different global standards?

A: This is achieved through CNC precision. The global market is divided between BSPT (British Standard) and NPT (American Standard). These threads have different angles (55° vs 60°) and different pitches. Jianzhi utilizes separate, dedicated CNC tooling for each standard. We use "Master Gauges" to verify the 1:16 taper ratio. It is a critical safety rule never to mix these threads in the field, as they will appear to fit but will eventually fail under pressure. Jianzhi clearly marks packaging to prevent these field errors.

Q5: What does "UL Listed" and "FM Approved" actually mean for a project?

A: These certifications are independent validations of safety. UL (Underwriters Laboratories) focuses on the structural integrity and burst pressure of the fitting. FM (Factory Mutual) focuses on property loss prevention, ensuring the fitting survives fires and mechanical shocks. For a contractor, using UL/FM certified Jianzhi fittings means the installation will pass fire marshal inspections and the building owner can secure lower insurance premiums because the risk of a catastrophic pipe failure is minimized.

Q6: Is it necessary to use thread sealant with Jianzhi tapered fittings?

A: Yes. While our 1:16 taper is designed for an interference fit (metal-to-metal contact), no machined thread is perfectly smooth at a microscopic level. A high-quality thread sealant or PTFE tape fills the microscopic valleys between the crests and roots of the threads. Because Jianzhi threads are cut to a high degree of "Squareness," you will find that less sealant is required to achieve a gas-tight joint compared to "light-type" generic brands.

Q7: Why do Jianzhi fittings weigh more than those of many competitors?

A: This refers to our "Heavy Type" philosophy. Many factories reduce the wall thickness ($t$) of their fittings to save on raw material costs. However, according to Barlow’s Formula, reducing thickness directly lowers the burst pressure. Jianzhi maintains a wall thickness that is 15-20% higher than the industry minimum. This provides a "corrosion allowance" and ensures that if a pipe is over-tightened by a high-torque wrench, the fitting will not split.

Q8: How does Jianzhi support "Green Building" and sustainability?

A: In 2025, sustainability is a key metric. Jianzhi fittings are made from 90% recycled ferrous scrap. Our electric induction furnaces are powered by increasingly renewable energy grids, significantly reducing the carbon footprint compared to traditional coke-fired cupolas. Furthermore, because of our superior material performance and 12% elongation, a Jianzhi system has a lifespan of 50+ years, reducing the environmental impact of frequent infrastructure repairs.

Q9: What documentation can Jianzhi provide for high-spec government or oil/gas projects?

A: We provide a comprehensive documentation package, most notably the EN 10204 3.1 Mill Test Certificate (MTC). This document traces the specific batch back to the chemical melt and the mechanical test results. We also provide certificates of origin, UL/FM compliance letters, and ISO 9001 quality management certificates. This "paper trail" is vital for project audits and safety compliance.

Q10: What should I do if a fitting shows surface discoloration?

A: For a black pipe fitting, the surface is protected by an anti-rust oil. If stored in a high-humidity environment for a long time, some surface oxidation (orange tint) may occur. This is typically superficial and does not affect the structural integrity of the "Heavy Type" wall. However, for critical applications, the fitting should be wiped clean and re-oiled, or stored in its original double-walled Jianzhi packaging until the moment of installation.

Q11: How does Jianzhi maintain "Squareness" in 100% of its production?

A: Misaligned threads (where the pipe goes in at a slight angle) are a nightmare for installers. Jianzhi uses automated jigs in our CNC centers that clamp the fitting in a fixed position relative to the cutting head. We then use laser-alignment sensors to verify the axis. This ensures that every elbow is exactly 90° or 45°, making the installation of long, linear pipe runs much faster and stress-free for the labor force.

Q12: Can Jianzhi fittings be used for sub-zero (arctic) temperatures?

A: Yes, but with caution. Malleable iron remains ductile at temperatures down to approximately -20℃. For temperatures lower than this, the metal can undergo a "ductile-to-brittle transition." However, because of our high ferritic purity and low phosphorus content, Jianzhi fittings perform better in cold climates than standard grey iron. Engineers should always check the specific thermal derating tables provided in Section 4 of our manual.

1. ISO 49:1994 - Malleable cast iron fittings threaded to ISO 7-1. International Organization for Standardization.

2. ISO 7-1:1994 - Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances and designation.

3. ASME B16.3-2021 - Malleable Iron Threaded Fittings: Classes 150 and 300. American Society of Mechanical Engineers.

4. ASTM A197/A197M-00(2023) - Standard Specification for Cupola Malleable Iron. ASTM International.

5. UL 213 - Standard for Rubber Gasketed Fittings for Fire-Protection Service. Underwriters Laboratories.

6. FM Approval Class Number 1112 - Approval Standard for Ferritic Malleable Iron Threaded Pipe Fittings. FM Approvals.

7. ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, 10th Edition.

8. Disa Holding A/S (2025) - Technical Specifications for DISAMATIC Vertical Molding Technology.

9. EN 10204:2004 - Metallic products — Types of inspection documents. European Committee for Standardization.

10. Hebei Jianzhi Casting Group (2025) - The "Heavy Type" Engineering Manual: Pressure Performance and Seismic Resistance. Internal Technical Whitepaper.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania