May. 23, 2022

We often get this question from customers who are often trying to determine if they should use malleable iron fittings or wrought iron threaded fittings or socket weld fittings.

Malleable iron fittings are lighter fittings in the 150# and 300# pressure classes. They are rated for pressures up to 300 psi and are built for light industrial and pipeline use. Some malleable fittings, such as floor flange, lateral, street tee and bullhead tees, are generally not suitable for wrought iron.

Malleable iron pipe fittings

The malleable iron is a cast iron. Cast iron is an iron carbon alloy with a carbon content between 2%-4.3%. The carbon content of industrial students is generally 2.11%-4.3%, and contains C, Si, MN, S, P and other elements, which is smelted by iron ore by blast furnaces. Depending on the form of carbon in the cast iron, it can be divided into several types of steelmaking raw iron, casting raw iron, and ductile iron.

Malleable iron is formed by refining the raw iron to iron solution and then casting it. It is hard, abrasion-resistant, and cast well. It can partially replace carbon steel but it is crispy and cannot be forged. It can be used for steelmaking or casting utensils.

The main component of malleable iron and forging iron are iron. The main difference between the two is that the amount of carbon-containing is different. Malleable iron is generally 2-4.3% of carbon-containing carbon and 0.03-2% of forging iron. At high temperatures, excessive carbon contained in the iron and other harmful impurities (such as sulfur, phosphorus, etc.) are oxidized by oxidant (such as oxygen), so that they can reach the specified range of steel content.

Malleable iron is divided into four categories: black-heart malleable iron, pearlitic malleable iron, white-heart malleable iron and ductile malleable iron according to chemical composition, heat treatment process, performance, and structure. At present, more than 90% of malleable iron produced in China is black-heart malleable iron. The other three types of malleable iron are less used. Black-heart malleable iron is not strong, but has good plasticity and toughness. Malleable cast iron is mainly used for shock and vibration parts such as rear axle housing, steering mechanism, low pressure valve, pipe joint and so on.

The grade of malleable cast iron is expressed by the percentage of the minimum tensile strength value (MPa) and the minimum elongation after fracture attached to "KTH" or "KTZ". For example, the grade KTH 300-06 represents the black-heart malleable cast iron with the minimum tensile strength of 300 MPa and the minimum elongation after fracture of 6%, which is the national standard requirement. Jianzhi uses KTH330-08.

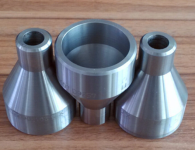

Forging iron pipe fittings

The forging iron is cooked iron. Wrought iron pipe fittings are pipe fittings with certain mechanical properties, certain shape and size, which are formed by applying pressure to metal blanks by forging machinery to produce plastic deformation. Through the continuous beating of the pipe fittings, the original looseness, pores, and slag inclusions in the steel ingot are compacted and welded, and the structure becomes more compact, which improves the plasticity and mechanical properties of the metal.

Forging iron is a more pure iron refined with raw iron, which can cause other shapes from solid iron high-temperature forging. It has toughness, delay, low strength, easy forging and welding, but cannot quench.

Forging iron fittings can be used as socket welded fittings or threaded fittings. Forged fittings are made of A105 (carbon steel), stainless steel or nickel alloys. These accessories are thicker and heavier for heavy industrial use. Wrought iron pipe fittings are available in four pressure grades: 2000#, 3000#, 6000# and 9000#. 3000# and 6000# fittings are more common. Threaded and socket welded fittings are available up to 4 inches.

The appearance of forging iron pipe fittings is very smooth, and the sound made when knocking is crisp.

Malleable iron fittings and forging iron fittings differ in material metallurgy, pressure rating, and application. It is important to make an appropriate choice between them for the intended application.

Our factory has the ability to develop molds that enable us to produce customized products according to customers' drawing requirements. If you would like to learn more about selling malleable iron accessories, or if you have any questions about these accessories or would like to purchase them, please contact us

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania