Nov. 11, 2022

In the installation process of the piping system, it is very important to confirm the thread type and size of the pipe fittings. If the thread type and size of the pipe fittings are wrong, the pipe fittings will not be installed smoothly, and it will take a lot of time to find the right pipe fittings. This will seriously delay the construction progress of the project and bring you unnecessary losses.

Common pipe fitting threads are as follows: NPT, PT, G, etc.

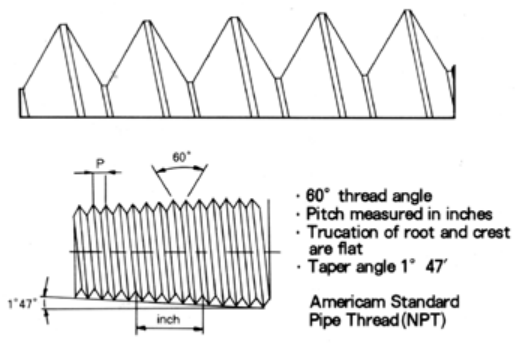

NPT thread <National (American) Pipe Thread> is the American standard 60degree pipe thread, which is divided into general sealing cylindrical pipe thread and general sealing tapered pipe thread.

● The theoretical position of the datum plane of the conical external thread of the American general sealing thread is located in the plane that is perpendicular to the thread axis and has a datum distance (L1) from the small end (datum plane);

● Basic size:

Thread pitch diameter D2=d2=D-0.8*P

Thread diameter D1=d1=D-1.6*P

● Connection method:

There is a post/cone fit between a cylindrical internal thread and a tapered external thread; a cone/cone fit between a tapered internal thread and a tapered external thread.

● Tolerance

The maximum deviation of the axial position of the reference plane of the American-made general sealing taper thread is -P~+P;

● Thread length

The minimum effective thread length of the U.S. general seal tapered male thread is not less than the actual diameter of its reference distance plus the assembly allowance.

The minimum effective thread length for general-purpose sealing threads made in the United States is at least the deviation from the reference plane position plus the basic dimension of the reference distance plus the assembly allowance;

● Marking

American general sealing pipe threads are marked as follows: thread feature code, thread size code, rotation code;

American general seal tapered pipe thread code: NPT

American general seal cylinder internal thread code: NPSC

For example, the size code is 4, and the left-hand American universal taper pipe thread is:

Chinese standard is NPT 4-LH

US standard is 4-8NPT-LH

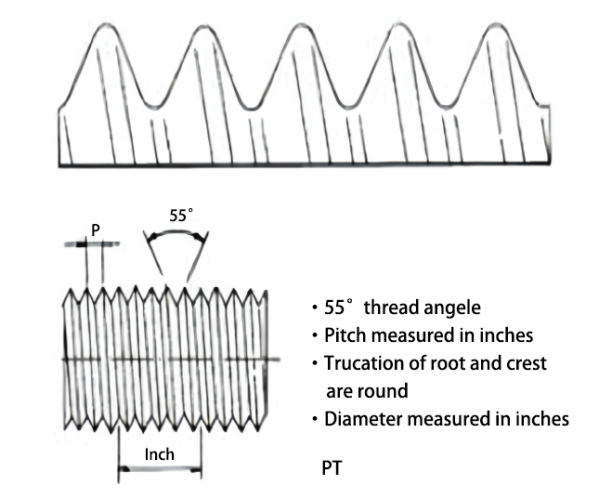

PT (BSPT) thread <British Standard Pipe Thread> is the abbreviation of Pipe Thread. Pipe thread with a 55degree sealing angle. It is the Wyeth thread. Mainly used in Europe and the Commonwealth of Nations. Usually used for water and gas pipes. The taper is 1:16, see the national standard GB/T7306-2000. Also known as ZG.

PT also stands for Japanese and Korean British sealing pipe threads. JIS B 0203 and KS B 0222 are Japanese and Korean standard numbers. GB/T 7306.2 is the corresponding Chinese standard.

BSPT thread

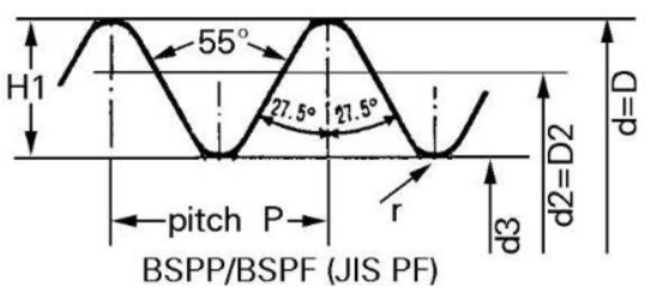

G is a 55degree unsealed pipe thread, which belongs to the Wyeth thread family. "G" stands for the cylindrical thread. See GB/T7307-2001 for national standards.

Joseph Whitworth, the inventor of the Wyeth thread, established his own machine tool factory during the wave of the British Industrial Revolution. Various thread factories, due to the lack of a unified thread standard, manufacture threads according to their own experience, resulting in different size ranges. The result is that it is difficult to interchange threaded parts. After replacing the screws, the screw holes in the same position on the same part may not be locked tightly.

As production continued to expand, Whitworth realized this serious problem. He then collects samples from different factories, measures sizes, and shapes, and collects other data. On this basis, he proposed a unified standard for thread processing, which is the origin of the Whitworth thread BSW (British Standard Whitworth), which is also the world's first thread standard.

The thread profile angle in this standard is 55 degrees (BSF = British Standard Whitworth Thread Fine).

G thread

Although Whitworth threads are no longer common in nuts and screws, they have been superseded by the Uniform and Metric series. However, BSPP (British Standard Parallel Pipe) and 1:16 BSPT (British Standard Pipe Tape) were developed on this basis, and have now become international standards (ISO), which are still in use today.

A G is an abbreviation for gas (derived from the German Gawande, meaning "thread"), as it was originally used in natural gas pipeline systems. Thread G consists of internal and external threads for non-sealing connections. The implementing standard is BS EN ISO 228-1, while the old standard is BS 2779, which is no longer valid.

Measuring pipe thread size is the most confusing part for many because thread size is not based on standard measurement units. Use a caliper, tape measure, or ruler to measure the thread diameter of male or female threads. Measure the inner diameter (ID) of the female thread and the outer diameter (OD) of the male thread. This number will help determine thread size.

The video below shows the process of measuring the diameter of the internal thread with a vernier caliper. You can learn from it and master the relevant measurement methods. It is worth noting that when using the vernier caliper to measure the internal thread, the vernier caliper must be extended to the maximum, otherwise the measurement will be inaccurate.

https://www.youtube.com/shorts/_68Lfb-AMuk

Okay, I believe you already understand the various types of pipe threads and how to measure them. You are welcome to continue to browse other content on our website, this website contains a lot of knowledge about malleable pipe fittings, it can be said to be a huge knowledge treasure, I believe you can get more knowledge from it. Of course, if you are interested in our products, you can leave your contact information, and our salesmen will give you professional answers.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania