Sep. 08, 2025

A 45-degree galvanized elbow’s job is simple: keep pipe flow turning smooth, whether it’s water lines, fire protection pipes, or HVAC ducts.

But here’s the catch: even the best elbow leaks if installed wrong. Below’s a simple step-by-step to get tight, reliable connections every time.

The catch? Even top elbows leak with bad installs. Here’s a quick step-by-step for tight, reliable connections.

But note: botch the install, and even the best elbow leaks. Below’s a simple guide for solid, leak-free connections.

Don’t rush this—bad prep leads to rework:

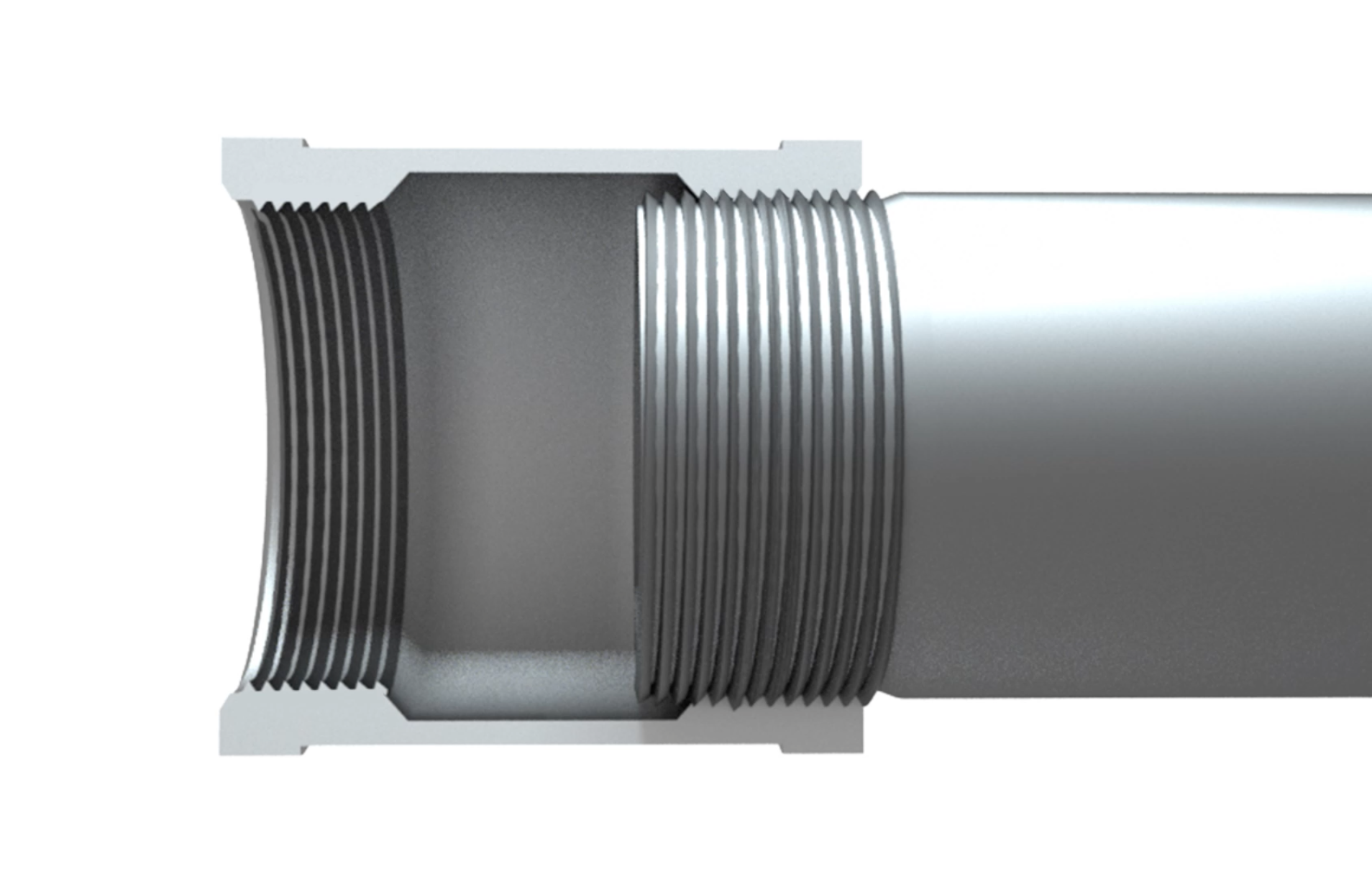

Check the elbow: Run a finger over the threads (no burrs or strips!) and make sure the galvanizing is even (no gaps or flaking). A faulty elbow can’t seal right.

Grab tools/materials: Get a pipe wrench (wrap a soft cloth around the jaws to protect galvanizing) and thick PTFE tape (avoid cheap, thin rolls that tear).

This is your first leak defense—do it correctly:

Direction: Face the pipe threads and wrap clockwise. Counterclockwise wrapping unwinds when you screw the elbow on.

Thickness: 4-6 wraps. Too few = loose seal; too many = tape bunches up and blocks pipes. Pull gently while wrapping to help it conform to the threads.

Tension is key—avoid two extremes:

Hand-screw first: Twist the elbow on by hand; you should get 2-3 easy turns. If it sticks, stop—cross-threading ruins parts. Wipe threads clean and try again.

Wrench-tighten: Use the cloth-wrapped wrench to turn 1/4 to 1/2 more turns. That’s enough to compress the tape and seal. Overtightening strips threads or cracks the elbow—stop if you hear a creak.

“Looks tight” isn’t enough—pressure-test to be sure:

Turn on water/air to the system’s working pressure.

Spray soapy water on the elbow joint. Bubbles mean a leak—relieve pressure, add 1-2 more tape wraps, and retighten.

Let pressure hold for 15-20 minutes. No pressure drop = good to go.

Counterclockwise tape: Unwinds during installation—always go clockwise.

Overtightening: Breaks parts and causes future leaks. Stick to 1/4-1/2 turns.

Skipping the test: Tiny leaks grow into big problems later. Don’t skip this step.

Even perfect steps fail with a bad elbow. JIANZHI galvanized elbows have precise threads, thick zinc coating, and strong malleable iron—so installation is easier, and leaks are rare.

Need reliable 45-degree galvanized elbows? Reach out for specs, pricing, or samples—we’ll help you get parts that make your job smoother.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania