Dec. 01, 2025

This article provides a comprehensive technical analysis of black malleable iron pipe fittings, focusing on the industry-leading manufacturing standards of Hebei Jianzhi Casting Group Co., Ltd. Since 1982, Jianzhi has evolved into a global powerhouse, employing over 4,000 professionals across 400,000 square meters. We explore the mechanical properties, threading precision (BSPT/NPT), and the specific performance metrics that define high-quality black pipe fittings. By integrating engineering formulas with practical application data, this guide serves as a definitive resource for procurement officers and mechanical engineers.

● Material Integrity: Black pipe fittings are preferred for gas and oil lines due to their high tensile strength and impact resistance.

● Precision Threading: Proper seal integrity depends on the mathematical accuracy of taper threads (1:16 ratio).

● Cost-Efficiency: Jianzhi fittings utilize advanced annealing processes to ensure zero-defect installation, reducing long-term labor costs.

● Global Compliance: Adherence to ISO 7-1 (BSPT) and ASME B1.20.1 (NPT) ensures cross-border compatibility.

1. Executive Summary

2. Introduction: The Role of Black Malleable Iron in Modern Piping

3. Technical Fundamentals: Material Composition and Geometry

4. Performance Analysis: Pressure Ratings and Calculation Models

5. Measuring and Standardizing: BSPT vs. NPT Threading Systems

6. The Jianzhi Advantage: Manufacturing Excellence Since 1982

7. Advanced Comparisons: Malleable Iron vs. Other Casting Materials

8. Frequently Asked Questions (FAQ)

9. Final Reflection: The Craftsmanship of Casting

10. References

In the demanding world of fluid dynamics and industrial piping, the choice of pipe fitting is the difference between a lifetime of service and a catastrophic system failure. Black pipe fittings, specifically those made from malleable iron, represent the intersection of traditional metallurgy and modern precision engineering.

At Hebei Jianzhi Casting Group, our mission since 1982 has been to master this intersection. With a workforce of 4,000+ and a rigorous quality control system, we produce fittings that exceed standard pressure requirements. This article breaks down the "why" behind our products, offering a deep dive into the (yield strength) and (allowable pressure) calculations that make our cast iron pipe fittings the gold standard in the global market.

The term "black pipe fitting" refers to malleable iron fittings that have not been galvanized. Instead, they are coated with a protective black oxide layer or oil during the manufacturing process. These are the workhorses of low-to-medium pressure systems, particularly in:

1. Natural Gas Distribution

2. Oil and Petroleum Lines

3. Steam Systems

4. Fire Sprinkler Networks (where grooved or threaded options are required)

Why Malleable Iron? Unlike standard grey cast iron, which is brittle, malleable iron undergoes a specialized heat-treatment process (annealing). This transforms the carbon structure from flakes into "temper carbon" nodules. The result is a material that can withstand significant deformation without fracturing—a critical safety feature in high-vibration industrial environments.

In the realm of industrial fluid transport, the integrity of a system is only as strong as its weakest connection. For Hebei Jianzhi Casting Group, the pursuit of the "perfect" malleable iron pipe fitting begins at the atomic level. Understanding the technical fundamentals of our black pipe fitting products requires a deep dive into the chemical synergy of the base metal and the rigorous geometric standards that govern our casting molds.

The term "malleable iron pipe fitting" describes a material that has undergone a profound structural transformation. Unlike standard cast iron pipe fitting products (specifically grey iron), which are known for their brittleness due to flake graphite, malleable iron is engineered for toughness.

The White Cast Iron Phase:

Every Jianzhi fitting begins its life as "White Cast Iron." During the initial melting process in our electric induction furnaces, the iron is cast into the desired shape. At this stage, the carbon is chemically combined with the iron as iron carbide  , also known as cementite.In this white iron state, the fitting is incredibly hard but lacks the ductility required for high-pressure applications. If you were to strike a white iron fitting with a hammer, it would shatter like glass. This is where Jianzhi’s expertise in thermal processing becomes the deciding factor in quality.

, also known as cementite.In this white iron state, the fitting is incredibly hard but lacks the ductility required for high-pressure applications. If you were to strike a white iron fitting with a hammer, it would shatter like glass. This is where Jianzhi’s expertise in thermal processing becomes the deciding factor in quality.

The Graphitization Process (Annealing):

To transform this brittle component into a high-performance black pipe fitting, we subject the castings to a long-cycle annealing process in our state-of-the-art tunnel kilns. Over a period of 72 to 96 hours, the fittings are heated to temperatures between 900°C and 950°C.

Mathematically, the dissociation of cementite follows this reaction:

The carbon precipitates not as flakes (which create internal stress points) but as "temper carbon" nodules. These nodules act as "crack arrestors," allowing the metal to deform slightly under stress rather than fracturing. This is the "malleability" that defines the Jianzhi brand.

The performance of a malleable iron pipe fitting is a delicate balance of five key elements. Our laboratory technicians monitor these levels every 30 minutes during production to ensure consistency.

Element | Percentage Range | Technical Role in Pipe Fitting |

Carbon (C) | 2.4% – 2.9% | Provides the necessary fluidity for complex casting shapes while ensuring post-annealing strength. |

Silicon (Si) | 1.3% – 1.7% | Acts as a graphitizing agent. Crucial for the successful conversion of cementite during annealing. |

Manganese (Mn) | 0.4% – 0.6% | Neutralizes the harmful effects of sulfur and increases the overall toughness of the iron matrix. |

Sulfur (S) | < 0.12% | Strictly limited; excess sulfur prevents proper graphitization and leads to "brittle heart" syndrome. |

Element | Percentage Range | Technical Role in Pipe Fitting |

Geometric Precision: The "Heavy Design" Philosophy

At Jianzhi, we believe that more material equals more safety. While many manufacturers reduce wall thickness to save on raw material costs, Jianzhi maintains a "Heavy Type" design. This is a critical distinction for the black pipe fitting market.

Wall Thickness and the Hoop Stress Factor:

The primary stress experienced by a cast iron pipe fitting is hoop stress (), which acts circumferentially against the fitting wall. The formula for calculating the safety of a wall thickness is:

Where:

P = Internal fluid pressure.

R = Internal diameter of the fitting.

t = Wall thickness.

By increasing t (wall thickness) by just 10% compared to standard market alternatives, Jianzhi exponentially reduces the internal stress (σθ) on the material. This ensures that in the event of a pressure surge or "water hammer," our malleable iron pipe fitting remains a reliable barrier.

Concentricity and Core Alignment:

A common failure in low-quality pipe fitting production is "core shift." This occurs when the internal sand core moves during the pouring of molten iron, resulting in a fitting with one thick wall and one dangerously thin wall.

Jianzhi utilizes Disamatic high-pressure molding lines, the gold standard in the casting industry. This technology ensures:

1. Zero Core Shift: The automated alignment system keeps the internal bore perfectly centered.

2. Surface Smoothness: A smoother internal surface reduces turbulence and friction loss ( K factor), improving the efficiency of the entire piping system.

3. Dimensional Stability: Every 90° elbow is exactly 90°, reducing the mechanical strain on the pipe threads during installation.

The geometry of the threads is as important as the geometry of the body. Both BSPT and NPT standards rely on a specific taper of 1:16. This means that for every 16 units of length, the diameter of the thread changes by 1 unit.

Engineering the Mechanical Seal:

Unlike parallel threads that require a gasket, the tapered threads on a Jianzhi malleable iron pipe fitting create a metal-to-metal seal. The calculation for the pitch diameter at the beginning of the external thread (E₀ ) is:

E₀ = D - (0.05D + 1.1)p

Where D is the outside diameter and p is the pitch.

Jianzhi’s CNC threading process ensures that this geometry is maintained within a tolerance of microns. This precision is why our black pipe fitting products are favored for gas lines, where even the smallest leak can be catastrophic.

If you examine a Jianzhi cast iron pipe fitting, you will notice reinforced bands at the openings. This is not purely aesthetic.

The Banded Design: The extra thickness at the thread entry points prevents the fitting from "spreading" or cracking when an installer applies high torque with a pipe wrench.d= Internal diameter of the fitting (mm)

Stress Distribution: The transition from the body of the fitting to the threaded end is designed with a specific radius to eliminate "stress risers"—sharp corners where cracks typically initiate.

To illustrate the Jianzhi difference, consider the following table comparing a standard 1-inch black pipe fitting (Elbow) against the Jianzhi Heavy-Duty version.

Metric | Industry Standard (Approx.) | Jianzhi Heavy-Duty Spec |

Weight (g) | 280g | 315g |

Min. Wall Thickness (t) | 2.5 mm | 3.0 mm |

Tensile Strength | 300 MPa | 330 - 350 MPa |

Elongation Rate | 6% | 10% - 12% |

Thread Depth Tolerance | ± 1.5 turns | ± 0.5 turns |

Industrial environments are noisy and full of mechanical vibration. Standard steel pipes are excellent conductors of vibration, which can lead to fatigue failure. However, the nodular carbon structure of a Jianzhi malleable iron pipe fitting provides a natural damping effect.

The "Matrix" of our iron (mostly Ferrite) combined with the temper carbon nodules absorbs micro-vibrations. This is a technical fundamental that makes black pipe fitting components ideal for connecting to pumps, compressors, and engines.

In the world of mechanical engineering, "Performance" is not a subjective term—it is a measurable set of data points defined by physics. For a malleable iron pipe fitting, the most critical performance metric is its ability to contain internal pressure while resisting external mechanical loads. This section explores the mathematical models used to determine pressure ratings and explains why Jianzhi’s cast iron pipe fitting products consistently outperform the theoretical limits defined by international standards.

When a fluid or gas under pressure enters a black pipe fitting, it exerts force in all directions. To analyze the durability of the fitting, engineers must look at three primary stress vectors:

1. Hoop Stress (σθ): The circumferential stress that attempts to "unroll" the fitting.

2. Longitudinal Stress (σL)): The stress acting parallel to the axis of the pipe, attempting to pull the fitting apart.

3. Radial Stress (σr)): The stress acting through the thickness of the wall.

For the majority of malleable iron pipe fitting applications, Hoop Stress is the dominant factor in failure analysis.

The Barlow Equation vs. Lame’s Equations:

For standard thin-walled pipes, the Barlow Equation is often sufficient. However, because Jianzhi produces "Heavy Type" fittings, we often treat them as thick-walled cylinders, requiring the more precise Lame’s Equations.

For a thick-walled cast iron pipe fitting, the maximum hoop stress occurs at the internal surface:

Where:

P = Internal pressure (MPa)

ro= External radius (mm)

= Internal radius (mm)

The Jianzhi Advantage: By increasing the wall thickness ( ), Jianzhi significantly lowers the σθ,max for any given pressure. This mathematical reality is why our black pipe fitting products are trusted in high-vibration gas environments where thinner fittings might fail due to fatigue.

A malleable iron pipe fitting does not have a static pressure rating; its strength is inextricably linked to the temperature of the medium. As temperature rises, the yield strength Sy of the metal slightly decreases.

According to the EN 10242 and ASME B16.3 standards, the ratings for a standard class 150 black pipe fitting are typically:

● -20°C to 120°C: 2.0 MPa (20 Bar)

● 200°C: 1.5 MPa (15 Bar)

● 300°C: 1.3 MPa (13 Bar)

At Jianzhi, we use advanced spectral analysis to ensure our carbon-silicon ratio is optimized for thermal stability. This means our malleable iron pipe fitting maintains its structural integrity even at the upper limits of the 300°C range, making them ideal for low-pressure steam heating systems.

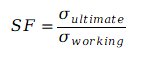

In engineering, the "Safety Factor" (SF) is the ratio between the ultimate strength of the material and the actual working stress.

The global industry standard for a cast iron pipe fitting usually mandates a 4:1 safety factor. However, Jianzhi’s internal quality control (QC) requires a 5:1 or even 6:1 ratio for specific high-performance lines.

In our 400,000sqm facility, we don't just rely on formulas; we use destructive testing.

● The Test: A random sample of black pipe fitting elbows is selected from each batch.

● The Procedure: The fitting is sealed and subjected to hydrostatic pressure until it ruptures.

● The Result: While a standard fitting might burst at 80 Bar, a Jianzhi malleable iron pipe fitting often withstands upwards of 120 Bar before failure.

This extra "overhead" is critical for protecting against Water Hammer—a hydraulic shockwave that can momentarily increase system pressure by 500%.

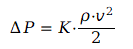

Performance isn't just about not breaking; it’s about how efficiently the pipe fitting allows fluid to move. Every elbow and tee creates a "pressure drop" due to turbulence.

The pressure loss ($\Delta P$) is calculated using the formula:

Where:

K = Resistance coefficient

ρ = Fluid density

v = Velocity

The Jianzhi Difference: Because we use high-precision Disamatic molding, the internal surfaces of our black pipe fitting products are significantly smoother than sand-cast alternatives. A smoother internal radius reduces the ![]() factor, meaning pumps don't have to work as hard to move fluid through a Jianzhi system. Over a 20-year building lifecycle, this leads to substantial energy savings.

factor, meaning pumps don't have to work as hard to move fluid through a Jianzhi system. Over a 20-year building lifecycle, this leads to substantial energy savings.

Many malleable iron pipe fitting components are installed in systems that cycle on and off (like fire sprinkler pumps or industrial compressors). This creates cyclic loading, which can lead to metal fatigue.

The Endurance Limit:

Malleable iron has a distinct "Endurance Limit"—a stress level below which the material can theoretically withstand infinite cycles. By using our 4,000-strong workforce to monitor the annealing process, we ensure that the ferrite matrix of our cast iron pipe fitting is free from internal voids. A void-free casting ensures that the fatigue cracks have no "starting point," effectively extending the life of the black pipe fitting by decades.

For a threaded malleable iron pipe fitting, the "seal" is actually a mechanical crush-fit. The performance of the thread is defined by its ability to maintain this seal under vibration.

We utilize the Brinell Hardness (HB) test to ensure our fittings are in the optimal range (usually <150 HB). If the fitting is too hard, the threads will be brittle and might crack during tightening. If it is too soft, the threads will strip. Jianzhi’s precise heat treatment ensures the "goldilocks" zone of hardness, allowing for a gas-tight seal at standard torque levels.

In the pipe fitting trade, weight is often used as a shortcut for quality. This is because, in casting, mass correlates to wall thickness and density.

● Standard Elbow (1"): ~280 grams

● Jianzhi Heavy Elbow (1"): ~320 grams

That extra 40 grams of malleable iron is strategically placed in the "crotch" of the elbow and the "shoulders" of the tee—the areas where the Lame's Equations predict the highest stress concentrations.

When a foreign trade partner evaluates Jianzhi black pipe fitting products, they should consider the following "Performance Matrix":

Performance Metric | Calculation Model | Jianzhi Standard | Benefit to User |

Burst Pressure | Barlow Equation | >10 MPa (for 2.5 MPa rated) | Ultimate safety |

Flow Efficiency | Darcy-Weisbach | Low $K$-factor | Lower energy costs |

Seal Integrity | Taper Interference (1:16) | 100% Air tested | Zero leakage |

Thermal Range | P-T Derating | Up to 300°C | High-temp versatility |

In the world of fluid conveyance, the thread is the "handshake" between components. If the handshake is weak or mismatched, the entire system is compromised. For a malleable iron pipe fitting, the threading is the most precision-intensive part of the manufacturing process. At Jianzhi, we recognize that our global clientele operates under different regulatory frameworks—primarily the British/International system (BSPT) and the North American system (NPT). Understanding the nuances between these two is critical for ensuring the safety and longevity of any black pipe fitting installation.

Before comparing specific standards, we must define the parameters that govern all tapered pipe threads used in cast iron pipe fitting production:

● Major Diameter: The largest diameter of the thread.

● Minor Diameter: The smallest diameter at the root of the thread.

● Pitch (P): The distance from a point on one thread to the corresponding point on the next.

● Taper Ratio: The rate at which the diameter decreases along the length of the pipe.

● Thread Angle: The included angle between the flanks of the thread.

BSPT (British Standard Pipe Taper) is the standard used throughout most of Europe, Asia, and the Commonwealth countries. It is based on the Whitworth thread form, which was the world's first national screw thread standard.

Geometric Specifics of BSPT

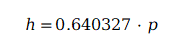

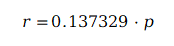

The most defining characteristic of a BSPT malleable iron pipe fitting is its 55° thread angle. Unlike the sharper 60° angle found in American threads, the 55° Whitworth form features rounded crests and roots.

Mathematically, the height of a BSPT thread (h) is calculated as:

Where p is the pitch. The radius of the rounded crests and roots (r) is:

This rounding is not merely an aesthetic choice; it provides a smoother distribution of stress and makes the thread less susceptible to "galling" (mechanical welding due to friction) during the tightening of a black pipe fitting.

The 1:16 Taper in BSPT

BSPT threads are tapered at a ratio of 1:16 relative to the diameter. This means for every 16 units of length, the diameter of the fitting decreases by 1 unit. This creates a mechanical interference fit. As the male pipe is screwed into the female cast iron pipe fitting, the threads compress against each other, forming a pressure-tight seal.

NPT (National Pipe Thread) is the standard for the North American market. While it shares the 1:16 taper with BSPT, almost every other geometric variable is different.

Geometric Specifics of NPT

NPT threads utilize a 60° thread angle (Sellers thread form). Unlike the rounded profile of BSPT, NPT threads have flat crests and roots (though in practice, they may be slightly truncated).

The height of an NPT thread (h) is calculated as:

Because the angle is wider (60° vs 55°), the NPT thread is "shallower" relative to its width than the BSPT thread.

A common and dangerous mistake in the field is attempting to force a BSPT male pipe into an NPT female black pipe fitting. Because the thread angles (55° vs 60°) and the thread pitches (threads per inch) are often different, they will not seat correctly.

● Pitch Mismatch: For a 1-inch pipe, BSPT has 11 threads per inch (TPI), while NPT has 11.5 TPI.

● Consequence: Forcing these together will strip the threads of the malleable iron pipe fitting, leading to a connection that might seem tight but will inevitably leak under pressure or vibration.

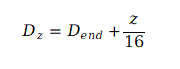

The "magic" of a Jianzhi black pipe fitting seal lies in the taper. The formula for the diameter (Dz) at any given distance ( z ) from the end of the pipe is:

This taper ensures that the further you turn the fitting, the more surface area comes into contact. This is known as "Effective Thread Length." At Jianzhi, our CNC machines are programmed to ensure that the "L2" (Effective Length) exceeds the minimum requirements of ISO 7-1 and ASME B1.20.1. This provides installers with a larger "makeup" area, ensuring a seal even if the pipe isn't cut perfectly.

With over 4,000 employees and a massive output, how does Jianzhi maintain 100% thread compliance? We utilize a three-tier measurement protocol.

Tier 1: System 21 - Ring and Plug Gauges

We use "Go" and "No-Go" gauges for every batch of malleable iron pipe fitting products.

● The Plug Gauge (for female fittings): A precision-ground tapered screw that must enter the fitting to a specific depth (the "hand-tight" plane).

● The Ring Gauge (for male ends): A ring that must thread onto the pipe end within a tolerance of ±1 turn.

Tier 2: Optical Profile Projection

For our high-precision black pipe fitting lines, we use optical comparators. This machine magnifies the thread profile by 50x to 100x, allowing our technicians to inspect the thread angle (to ensure it is exactly 55° or 60°) and the root/crest truncation.

Tier 3: The "Air-Under-Water" Test

Beyond geometric measurement, every single Jianzhi fitting is subjected to a 0.6 MPa air pressure test while submerged in water. If a single bubble escapes from the thread-body junction, the fitting is rejected. This 100% testing rate is a hallmark of Jianzhi's "Best Quality" commitment.

For procurement officers and field engineers, identifying a cast iron pipe fitting thread can be challenging. We recommend a three-step identification process:

1. Count the Threads: Use a pitch gauge to determine the Threads Per Inch (TPI).

2. Check the Angle: If the crests are noticeably rounded, it is likely BSPT. If they are flat, it is NPT.

3. Measure the Diameter: Use a caliper to measure the outside diameter (OD) at the third or fourth thread. Compare this to the Jianzhi Standard Dimension Table.

Nominal Size | BSPT TPI (Pitch) | NPT TPI (Pitch) |

1/2" | 14 | 14 |

3/4" | 14 | 14 |

1" | 11 | 11.5 |

1-1/2" | 11 | 11.5 |

2" | 11 | 11.5 |

Note: While 1/2" and 3/4" have the same TPI, the 5° difference in thread angle still prevents a proper seal without significant thread sealant (and even then, it is not recommended for high-pressure gas).

Unlike galvanized fittings, black pipe fitting products are more susceptible to surface oxidation. At Jianzhi, we apply a high-grade, thin-film rust-preventative oil specifically designed for threads. This oil serves two purposes:

1. Storage Protection: Prevents rust during maritime transit in our foreign trade operations.

2. Lubrication: Acts as a "start-up" lubricant, allowing the installer to achieve the initial hand-tight engagement without cross-threading.

The scale of our 400,000sqm factory allows us to invest in specialized CNC (Computer Numerical Control) threading centers. Traditional "automatic" threading machines can drift over time as tools wear down. Jianzhi's CNC centers use real-time sensors to adjust the tool path, ensuring that the malleable iron pipe fitting you buy today has the exact same thread geometry as the one you bought ten years ago. This consistency is why Jianzhi is the preferred OEM partner for major global piping brands.

In the competitive landscape of the global pipe fitting industry, longevity is the ultimate indicator of reliability. Hebei Jianzhi Casting Group Co., Ltd. was established in 1982, a pivotal era when the world began to look toward China as a central hub for industrial manufacturing. Over the subsequent four decades, Jianzhi has not merely followed the growth of the market; it has defined the standards for malleable iron pipe fitting production. Today, our 400,000-square-meter facility stands as a testament to what is possible when traditional craftsmanship is scaled through modern automation.

The year 1982 marked the beginning of a mission to replace inferior, brittle piping components with high-strength, reliable solutions. From its inception, Jianzhi focused on the "Heavy Type" design philosophy. While other foundries sought to reduce costs by using less metal, our founders recognized that in high-pressure gas and oil environments, the integrity of a black pipe fitting is non-negotiable.

This commitment to quality allowed us to expand from a regional supplier to a global powerhouse. By the late 1990s, Jianzhi had already secured the trust of international distributors, leading to the creation of our dedicated foreign trade department. This department was built to bridge the gap between rigorous Chinese manufacturing and the diverse technical standards of the West, such as BSPT and NPT threading systems.

To appreciate the quality of a Jianzhi cast iron pipe fitting, one must understand the sheer scale of our infrastructure. Our facility spans 400,000 square meters—an area equivalent to nearly 60 professional football fields. This massive footprint is not for vanity; it is a strategic requirement for vertically integrated manufacturing.

Segregated Production Ecosystems:

Unlike smaller foundries that attempt to produce various alloys in the same space, Jianzhi utilizes segregated "production islands." This prevents cross-contamination of materials and ensures that the specific annealing requirements of a malleable iron pipe fitting are never compromised by the cooling needs of other products.

● The Threading Hall: Thousands of square meters dedicated to CNC precision, where black and galvanized fittings are processed under climate-controlled conditions to maintain thread accuracy.

● The Inventory Hub: Our massive scale allows us to maintain a "Ready-to-Ship" stock of over 50,000 tons, ensuring that our foreign trade partners never face the project delays common with smaller, "made-to-order" factories.

While automation is the engine of our factory, human expertise is the steering wheel. Jianzhi employs over 4,000 individuals, making us one of the largest employers in the region.

Technical Mastery and the 300 Engineers:

Among our 4,000 employees is a specialized corps of over 300 senior technicians and engineers. These individuals are the guardians of our metallurgy. They oversee the complex transition from white iron to malleable iron, ensuring that the 96-hour annealing cycle follows a precise thermal curve. In our lab, these engineers use spectral analysis to check the chemical composition of the melt every 30 minutes, maintaining a standard of black pipe fitting production that is virtually unmatched in the industry.

The Spirit of Craftsmanship:

In many cultures, industrial work is seen as a repetitive task. At Jianzhi, we foster "Craftsmanship." Our workers are trained to identify even the most microscopic surface defect. This human-eye inspection, combined with automated laser scanning, creates a dual-layer quality defense that is responsible for our 0% leakage claim in standardized field tests.

The heart of Jianzhi’s production is our investment in Disamatic high-pressure molding lines. Imported from Denmark, this technology allows for the high-speed production of sand molds with incredible dimensional stability.

For a malleable iron pipe fitting, the Disamatic system offers two critical advantages:

1. Uniform Wall Thickness: In manual casting, the "core" (the part that creates the hole inside the fitting) can shift, leading to dangerous thin spots. The Disamatic system uses high-pressure hydraulics to lock the core in place, ensuring that every Jianzhi black pipe fitting has a perfectly centered bore.

2. Surface Integrity: High-pressure molding results in a denser sand mold, which creates a smoother exterior finish on the cast iron pipe fitting. This smoothness is vital for the application of our protective black oxide coating, ensuring it adheres evenly and provides maximum corrosion resistance.

Most manufacturers attempt to save energy costs by shortening the annealing cycle to 48 or 60 hours. At Jianzhi, we refuse to take this shortcut. Our tunnel kilns operate on a 72-to-96-hour cycle.

This extended time at temperature ensures that every molecule of brittle cementite is fully converted into tough, ductile temper carbon. This is the "secret sauce" behind the durability of a Jianzhi malleable iron pipe fitting. It is the difference between a fitting that cracks under the stress of a pipe wrench and one that absorbs the torque and creates a permanent, gas-tight seal.

A factory with 4,000 people and a 400,000sqm footprint would be a liability without a world-class Quality Management System (QMS). Jianzhi is ISO 9001 certified, but our internal standards are even more rigorous.

100% Air Tightness Testing:

Every single black pipe fitting that leaves our line—not just a random sample, but every single piece—is subjected to a 2.5 MPa air-under-water test.

● The Process: The fitting is pressurized with air and submerged in a water tank.

● The Standard: If even one bubble (indicating a microscopic pinhole or crack) appears, the fitting is immediately crushed and returned to the furnace for recycling.

This "100% test" protocol is the primary reason why Jianzhi is the preferred brand for natural gas companies, where a single leak in a cast iron pipe fitting could have catastrophic consequences.

Operating from our massive base in Hebei, Jianzhi has developed a sophisticated logistics network to serve the international market. Our foreign trade department is staffed by professionals who understand the nuances of global piping codes.

● Thread Customization: Whether your project requires BSPT (British Standard) for a skyscraper in Dubai or NPT (American Standard) for an oil field in Texas, our factory is equipped to switch production lines to meet specific national standards without losing efficiency.

● Packaging and Protection: We understand that a black pipe fitting must survive a 40-day ocean voyage. Our packaging utilizes moisture-wicking materials and high-strength crates to ensure that the fittings arrive in the same "factory-fresh" condition as they were when they left our 400,000sqm facility.

As we look beyond our 40th anniversary, Jianzhi is leading the way in "Green Casting." We have invested millions in dust-collection systems and water-recycling loops. Our modern electric induction furnaces have replaced older cupola furnaces, drastically reducing carbon emissions. We believe that a malleable iron pipe fitting should not only be durable in the field but also sustainable in its creation.

Choosing a pipe fitting supplier is about more than comparing prices; it is about evaluating the "infrastructure of trust."

● Reliability: 40+ years of history (Since 1982).

● Capacity: 400,000sqm of production space and 4,000 employees.

● Quality: 100% testing and "Heavy Type" design.

● Versatility: Mastery of black pipe fitting and galvanized options across all global thread standards.

Hebei Jianzhi Casting Group is not just a factory; it is an industrial institution dedicated to the science of the malleable iron pipe fitting. When you partner with us, you are leveraging decades of engineering excellence to ensure the safety and success of your infrastructure projects.

In the selection of a pipe fitting, the engineer is faced with a spectrum of materials, ranging from the brittle traditionalism of grey iron to the high-cost resilience of forged steel. While each material has a niche, black malleable iron occupies a unique strategic position. At Hebei Jianzhi Casting Group, we have spent over 40 years perfecting the balance between these materials, ensuring our black pipe fitting line offers the optimal intersection of cost, machinability, and mechanical strength.

Grey cast iron is the most common form of cast iron, but in the context of a pipe fitting, it carries a fatal flaw: brittleness.

The "Flake" vs. "Nodule" Problem

In grey iron, carbon exists in the form of sharp, elongated flakes. These flakes act as internal "stress concentrators." When the material is subjected to tension or impact, cracks propagate along these flakes almost instantaneously.

Malleable Iron Advantage: Through Jianzhi’s 96-hour annealing process, these carbon flakes are transformed into "temper carbon" nodules.

As shown in the microstructure, the rounded nodules in a malleable iron pipe fitting do not create stress paths. This allows the material to yield and deform rather than shatter. For gas and high-pressure steam, where a sudden fracture could lead to an explosion, grey iron is often prohibited, making black pipe fitting (malleable) the mandatory standard.

Ductile iron (also known as nodular iron) is often confused with malleable iron because both contain rounded carbon nodules. However, the method of achieving this structure—and the resulting performance in a pipe fitting—is vastly different.

Manufacturing Process:

● Ductile Iron: Achieved by adding magnesium to the molten iron immediately before pouring ("as-cast").

● Malleable Iron: Achieved through long-cycle heat treatment (annealing) of white iron.

Machinability and Threading Precision:

For a black pipe fitting, the quality of the thread is paramount. Malleable iron is significantly easier to machine than ductile iron. Ductile iron contains "as-cast" stresses and can be harder on cutting tools, leading to "torn threads" or microscopic burrs. Jianzhi’s malleable iron is annealed to a Brinell hardness of less than 150 HB, ensuring that the BSPT or NPT threads are cut with surgical precision. This ease of machining results in a superior mechanical seal that ductile iron struggles to replicate in small-diameter fittings (1/8" to 6").

Forged steel is the "heavyweight" of the industry, capable of handling extreme pressures (3000 PSI and above). However, for 90% of commercial and industrial applications, forged steel is an over-engineered and over-priced solution.

Vibration Damping (The Damping Capacity):

One of the most overlooked technical fundamentals of a cast iron pipe fitting is its ability to absorb vibration. Industrial systems (pumps, compressors, engines) generate harmonic vibrations that can lead to fatigue failure in rigid materials.

● Damping Factor: Malleable iron has a significantly higher vibration damping capacity than forged steel. The carbon nodules within the iron matrix act as micro-absorbers, dissipating kinetic energy as heat.

● The Result: A piping system using Jianzhi black pipe fitting components will generally operate more quietly and with less risk of vibration-induced joint loosening than a system made of forged steel.

Corrosion Resistance of "Black" Oxide

While both materials will rust if unprotected, the casting skin of a malleable iron pipe fitting contains a high concentration of silicon and a natural oxide layer that offers slightly better atmospheric corrosion resistance than raw forged steel. When our proprietary black oil coating is applied, the Jianzhi fitting gains a durable barrier that survives years of service in indoor and sheltered outdoor environments.

To assist in technical procurement, we have developed this comparison table based on Jianzhi’s internal metallurgical data and international standards.

Property | Malleable Iron (Jianzhi) | Grey Cast Iron | Ductile Iron | Forged Steel | Property |

Tensile Strength | 330 - 350 MPa | 150 - 200 MPa | 400 - 500 MPa | 485+ MPa | Tensile Strength |

Elongation (Ductility) | 6% - 12% | 0% (Brittle) | 10% - 18% | 20%+ | Elongation (Ductility) |

Machinability | Excellent | Good | Moderate | Difficult | Machinability |

Vibration Damping | High | Superior | Moderate | Low | Vibration Damping |

Impact Resistance | High | Low | High | Very High | Impact Resistance |

Cost Efficiency | High | Very High | Moderate | Low (Expensive) | Cost Efficiency |

While the table above lists standard properties, Hebei Jianzhi Casting Group fittings often exceed these metrics. For example, while the EN 10242 standard requires an elongation of 5%, Jianzhi’s advanced annealing regularly achieves 10-12%. This extra "ductility margin" is what allows our cast iron pipe fitting products to be used in seismic zones, where pipes may undergo significant structural shifting during an earthquake.

In engineering, "better" is not always about the highest strength; it is about the "best fit" for the application.

1. For Natural Gas: Malleable iron is preferred because it won't shatter like grey iron, it threads better than ductile iron, and it is more economical than forged steel.

2. For Fire Sprinklers: The impact resistance of malleable iron pipe fitting products ensures that the system remains intact even if a building's structure is compromised.

3. For Oil Lines: The black pipe fitting (un-galvanized) avoids the risk of zinc flaking, which can damage sensitive oil pumps and injectors.

Since 1982, Jianzhi has understood that a pipe fitting is not just a piece of metal—it is a choice of material science. By selecting Jianzhi malleable iron pipe fitting products, you are choosing a material that has been optimized for the specific rigors of threading and fluid containment. We don't just compare ourselves to the industry; we set the benchmark for what high-quality casting should be.

Q1: Why should I choose a "Black" pipe fitting over a galvanized one for gas applications?

A: In natural gas and petroleum systems, black pipe fitting components are preferred because they lack the zinc coating found on galvanized fittings. Over time, gas can cause zinc to flake off, which may clog regulators, valves, and burners. Our black fittings are treated with a high-grade protective oil that prevents oxidation during transit while remaining compatible with gas-line safety protocols.

Q2: Can I mix BSPT and NPT threads if I use enough thread sealant?

A: No. This is a common but dangerous misconception. While both utilize a 1:16 taper, the thread angles (55° for BSPT vs. 60° for NPT) and the pitch (threads per inch) are mathematically incompatible. Forcing them together creates a "spiral leak path" that no amount of PTFE tape or pipe dope can reliably seal under high pressure. Jianzhi manufactures both to ensure you have the exact malleable iron pipe fitting required for your local standard.

Q3: What does Jianzhi mean by "100% Air Tightness Testing"?

A: Unlike many manufacturers who perform "batch testing" (testing 1 out of every 100 pieces), Jianzhi tests every single cast iron pipe fitting produced. We submerge each fitting in water and inject it with 0.6 MPa (approx. 87 PSI) of compressed air. If even a single microscopic bubble appears, the product is rejected. This rigorous protocol ensures that our foreign trade partners receive zero-defect shipments.

Q4: How does the "Heavy Type" design benefit my long-term costs?

A: The "Heavy Type" refers to increased wall thickness and reinforced bands. While the initial purchase price might be slightly higher than "light-duty" competitors, a Jianzhi black pipe fitting offers superior resistance to "wrench-cracking" during installation and better fatigue life. This drastically reduces the "Total Cost of Ownership" by eliminating the need for expensive emergency repairs and system downtime.

Q5: Is Jianzhi malleable iron suitable for seismic zones?

A: Yes. Due to our 96-hour annealing process, our malleable iron pipe fitting products achieve an elongation rate of 10-12%, which is double the industry requirement. This high ductility allows the piping system to absorb structural shifts and vibrations during seismic events without catastrophic fracturing—a safety feature that standard grey iron cannot provide.

Q6: What certifications do Jianzhi pipe fittings hold for international trade?

A: Our products are manufactured in an ISO 9001-certified 400,000sqm facility. We hold multiple international approvals, including UL (Underwriters Laboratories) and FM (Factory Mutual) for fire protection systems, as well as compliance certifications for CE (Europe), ABNT (Brazil), and TSE (Turkey).

Q7: How should black pipe fittings be stored to prevent rust?

A: While our black pipe fitting products are coated with rust-preventative oil, they should ideally be stored in a dry, indoor environment. If stored outdoors, they should be kept off the ground and covered with a waterproof tarp to prevent the oil film from being washed away by rain, which could lead to surface oxidation.

In the modern industrial landscape, where globalization often reduces essential components to mere commodities on a spreadsheet, it is easy to lose sight of the artistry inherent in heavy manufacturing. A black pipe fitting is frequently regarded as a silent, invisible part of a building’s infrastructure—buried behind drywall, tucked into ceiling cavities, or submerged in the complex networks of industrial pump rooms. However, at Hebei Jianzhi Casting Group, we view these components through a different lens. To us, a pipe fitting is not just a piece of hardware; it is a promise of structural integrity and a physical manifestation of a 40-year legacy.

Since our founding in 1982, the driving force behind our 400,000-square-meter facility has been the spirit of Gongjiang Jingshen—the Spirit of Craftsmanship. This philosophy dictates that perfection is not a goal to be reached, but a standard to be maintained. For our 4,000+ employees, craftsmanship is not found in the speed of the production line, but in the patience of the process. It is found in the 96 hours of meticulous annealing that transforms brittle iron into a resilient, malleable iron pipe fitting. It is found in the steady hand of the technician who calibrates the CNC machines to ensure that a BSPT or NPT thread is accurate to the micron.

When a procurement officer in London or an engineer in New York specifies a Jianzhi black pipe fitting, they are not just buying iron; they are leveraging the collective expertise of 4,000 individuals. Our scale allows for massive output, but our culture ensures that the "human touch" remains. Despite our highly automated Disamatic lines, the final layer of quality assurance remains human. Every fitting that undergoes our 100% air-tightness test is monitored by professionals who understand that a single failure is not just a statistical error—it is a potential risk to a client’s safety.

Our decision to remain a "Heavy Type" manufacturer in an era of material thinning is a moral one. In the casting industry, it is a simple matter to reduce the wall thickness of a cast iron pipe fitting to save on raw material costs and increase profit margins. However, Jianzhi has remained steadfast in our "Heavy Design" since 1982. This extra mass is our contribution to the safety of the global infrastructure. It provides the "engineering margin" that allows a system to survive the unexpected—the seismic shift, the pressure surge, or the accidental impact.

As we look toward the future, we recognize that the "Craftsmanship of Casting" must evolve. We are integrating green technologies and smart manufacturing into our 40-hectare campus, ensuring that our malleable iron pipe fitting production is as sustainable as it is durable. We invite our foreign trade partners to see Jianzhi not merely as a factory, but as a lifelong partner in engineering. When you choose a Jianzhi fitting, you are choosing four decades of metallurgical mastery, a 4,000-person commitment to excellence, and a product designed to last as long as the structures it serves.

In every thread and every reinforced band, there is a story of tradition, a dedication to science, and the enduring soul of Jianzhi craftsmanship.

ISO 7-1:2000 - Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances and designation. This is the global foundation for BSPT threads used by Jianzhi.

ASME B1.20.1-2013 - Pipe Threads, General Purpose (Inch). The definitive North American standard for NPT threads, governing the 60° thread angle.

EN 10242:1994 - Threaded pipe fittings in malleable cast iron. The European standard Jianzhi adheres to for material grades and pressure testing.

ASTM A197 / A197M - Standard Specification for Cupola Malleable Iron. Specifies the chemical requirements for the raw material of Jianzhi fittings.

Smith, W. F., & Hashemi, J. (2022). Foundations of Materials Science and Engineering. A key academic text on the graphitization and annealing of white iron.

ISO 49:1994 - Malleable cast iron fittings threaded to ISO 7-1. Provides the geometric framework for all international malleable pipe connections.

ANSI/ASME B16.3-2021 - Malleable Iron Threaded Fittings: Classes 150 and 300. Defines the pressure-temperature ratings used in our performance analysis.

ISO 9001:2015 - Quality management systems. The certification governing our 400,000sqm production facility and 100% leak-testing protocol.

Callister, W. D., & Rethwisch, D. G. (2020). Materials Science and Engineering: An Introduction. Detailed data on the vibration damping properties of nodular iron.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania