Nov. 26, 2025

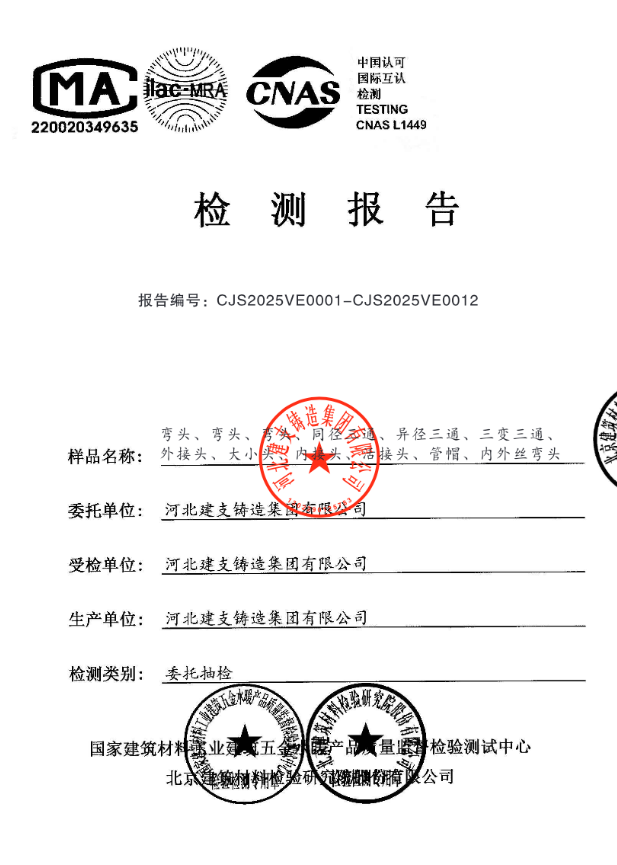

Proactively verifying material certifications, heat numbers, and pressure ratings is key to avoiding quality issues when procuring pipe fittings. Buyers should ask for mill test certificates, look over factory audit reports, and put pre-shipment inspection protocols in place. Doing so ensures everything lines up with the project’s specific requirements.

Always ask your supplier for MTCs. These documents need to cover three critical points:

● Material chemical composition and mechanical properties

● Heat number tracking (for full traceability)

● Pressure test results and official rating verification

Our factory includes a complete MTC package with every shipment. These certificates confirm all malleable iron pipe fittings meet ASTM A197 standards.

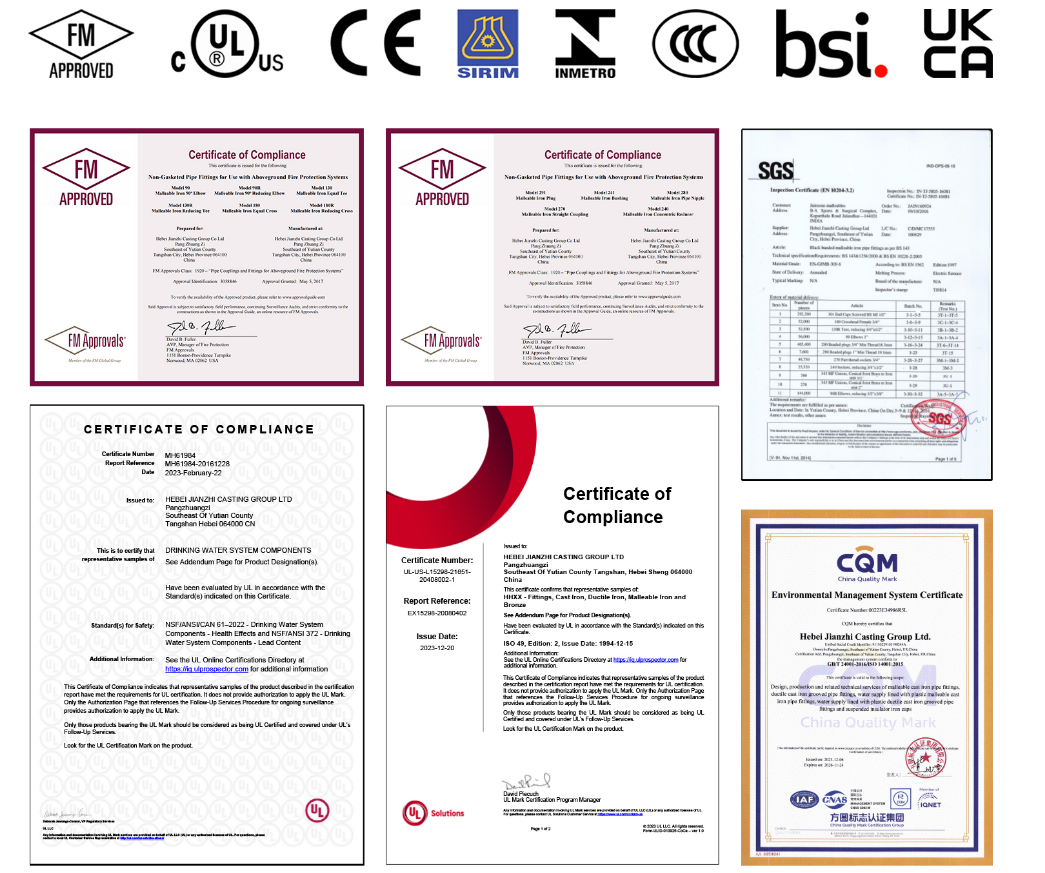

Take the time to check that key certifications are valid:

→ FM/UL certifications (for fire protection applications)

→ Regional compliance marks like ABNT, CE, and TSE

→ Current ISO 9001 quality management system status

We keep all relevant certifications up to date for both our galvanized and black malleable iron pipe fittings. All documentation is available for buyers to review upon request.

Schedule independent inspections to check these details firsthand:

☑ Material grade markings on the fittings themselves

☑ Heat number consistency (make sure they match what’s on the docs)

☑ Pressure rating compliance (specifically for Class 150 applications)

Our factory is happy to coordinate and facilitate client inspections and testing before shipments go out.

Take a close look at the supplier’s process capabilities, including:

● Heat treatment processes and complete record-keeping

● Quality control measures for galvanizing

● Checks to ensure dimensional accuracy

With 43 years in the industry, JIANZHI maintains thorough documentation of all our manufacturing processes. Clients are welcome to review these records anytime.

● Compare heat numbers on the fittings against the data in the MTCs

● Confirm pressure rating markings are clearly visible on each fitting

● Validate certification numbers directly with the issuing bodies

● Review independent factory audit reports

Our documentation process is fully transparent. This lets buyers confidently verify all quality parameters before shipment—cutting down on project risks and ensuring our Class 150 pressure-rated fittings perform reliably.

Protect your projects by choosing pipe fittings with proper documentation and full certification. Our comprehensive quality materials provide complete traceability and easy verification.

Contact us to request sample certifications and learn more about our quality verification process.

SAFER

PRODUCT INFO

ABOUT JIANZHI

TECH DATA

Contact Us

E-mail: sales1@jianzhi-fitting.com

Tel: +86 15822792427

Office In Tianjin:

Heping District, Tianjin, China.

Production Base 1:

Chifeng, Inner Mongolia, China.

Production Base 2:

Tangshan City, Hebei Province, China.

Production Base 3:

Schelei Street,Baicoi City,Prahova County,Romania